When your machine’s windshield wipers suddenly stop working, visibility can drop dangerously fast. Then, how to test a dead wiper motor? This quick 3‑step diagnostic guide walks you through how to find and fix the real problem — safely, accurately, and without wasted downtime.

Key Takeaways

- Begin with simple checks — fuses, corrosion, linkage blockage.

- Use a multimeter to separate wiring problems from motor faults.

- Ensure both power and ground are present before replacing parts.

- A bench test is the quickest way to confirm a bad motor.

- For wipers that don’t park properly, replace the full unit — it’s not serviceable.

Remember: In off‑road conditions, dust, vibration, and moisture accelerate corrosion and wear. Routine inspection of connectors and grounds can prevent many electrical issues before they cause downtime.

Preparation

Safety First

Before touching any electrical components:

- Turn the ignition OFF and remove the key.

- Disconnect the negative (–) battery terminal if you’re removing the motor or handling any connectors.

- Reconnect it later only when you’re ready for voltage testing.

Tools You’ll Need

Digital multimeter (essential for testing voltage and continuity)

Jumper wires (preferably with alligator clips)

Socket or wrench set

Machine wiring diagram or service manual

Tip: Always work on level ground, and ensure all hydraulic systems are at rest before starting any electrical inspection.

Step 1: Start with Simple Checks

Most wiper system failures come from basic issues — small, cheap, and easy to fix.

1. Check the Wiper Fuse

Find the wiper or “accessory” fuse in your machine’s fuse box or panel.

If it’s blown, replace it with one of the same amperage rating.

If it keeps blowing, there’s likely a short circuit or overloaded motor downstream.

2. Check the Wiper Switch & Related Functions

Try turning on the washer fluid pump (if equipped).

If the pump works, it’s a good clue that the switch is receiving power. However, this is not a final confirmation, as some machines use separate circuits for the wiper and washer functions.

If neither the wipers nor the washer responds, suspect an upstream electrical issue like a corroded connector or a bad switch.

3. Listen for the Motor

Turn the key to ON (engine not running), activate the wiper switch, and listen carefully near the base of the windshield.

- You hear humming or clicking: The motor is receiving power but may be jammed, or the linkage seized. Check the wiper arms, pivots, and linkage for rust, ice, or debris.

- Complete silence: Power may not be reaching the motor, or the motor’s circuits are internally burned out.

If nothing obvious turns up, move to electrical testing.

Step 2: Test for Power and Ground (Multimeter Method)

Now it’s time to confirm if your machine’s electrical system is doing its job.

1. Locate and Disconnect the Motor Connector

Find the wiper motor — usually mounted near the base of the windshield or under the hood/cowl.

Disconnect the plug, and you’ll test on the machine harness side, not the motor side.

2. Check for Power (12 V or 24 V)

- Turn the ignition ON.

- Set the wiper switch to LOW speed.

- Set your multimeter to DC Volts (20V range for 12V systems; 50V range for 24V machines).

- Black probe to the metal chassis ground.

- Using your wiring diagram to identify the correct pin, touch the red probe to the LOW-speed power terminal inside the connector.

- Expected result: You should see a voltage near your system’s operating voltage (12 V or 24 V).

- Switch to HIGH speed and test the corresponding HIGH-speed pin — it should now show voltage.

No reading? The issue lies upstream — check the switch, relay, or wiring harness.

3. Test Ground Connection

- Turn ignition OFF.

- Set your multimeter to Continuity () mode.

- Probe the motor ground pin (check your wiring diagram).

- Touch the other probe to a clean chassis ground.

A beep or zero resistance means the ground is solid. A poor ground can cause a host of confusing electrical issues, similar to telling the difference between a bad alternator vs a bad battery.

If not, trace the ground strap or wire — corrosion is common in harsh environments.

4. Check the Results

| Power | Ground | What It Means |

|---|---|---|

| Yes | Yes | Wiring is good — the motor is faulty. |

| No | Yes | Power problem — inspect fuse, relay, switch, or wiring. |

| Yes | No | Ground fault — clean or replace the ground wire. |

| No | No | System fault — trace wiring and main feed circuit. |

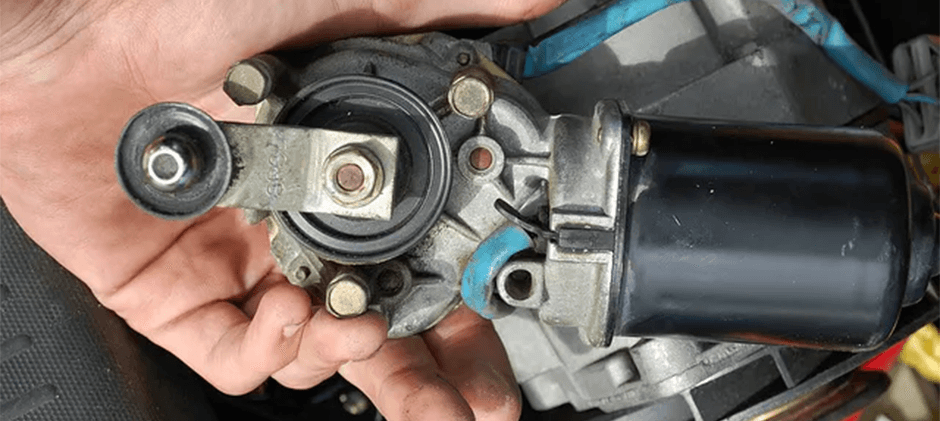

Step 3: Bench‑Test the Wiper Motor

If you’ve confirmed that power and ground are fine, it’s time to test the motor directly.

1️. Remove and Secure the Motor

Unbolt the motor and mount it securely on a non‑conductive surface or in a vice, away from grounded metal parts.

2. Connect to a Battery

- Use a power source that matches the motor’s voltage (12V or 24V). A dedicated DC power supply is safest.

- Connect one jumper wire from the motor’s ground pin to the power source’s negative (–) terminal.

- Connect another jumper wire from the power source’s positive (+) terminal and briefly touch it to the motor’s low‑speed power pin. Do not connect power to the park-switch pins.

If your machine runs on 24V, use both batteries in series to replicate that voltage.

3. Read the Results

- Motor spins normally: It’s good — your wiring or switch is faulty.

- No movement or sparks only: The motor’s internal brushes, armature, or park switch are likely burned out. Replacement is the right call.

Important: Apply power only briefly. Continuous running without a load can overheat the motor.

What If Wipers Move But Won’t Park

If your wipers work but never stop in their proper “rest” position, your internal park switch is likely defective.

This built‑in circuit controls automatic shut‑off when the wipers return to the base position.

Because it’s usually sealed inside the motor housing, replacement of the entire motor assembly is the most effective fix. You can follow a step-by-step replacement guide to do the job correctly.

Conclusion

By following these three simple diagnostic steps — inspect, measure, and test — you can quickly identify the real cause of failure without unnecessary part swaps.

With a systematic approach, you’ll not only save repair costs but also keep your machine ready for any job, any weather. If you want to find a high-quality wiper motor with ease, FridayParts is always waiting to cater to you.