The ignition switch is generally mounted on the dashboard or control panel of your equipment. It plays a key role in powering up most of the electrical and engine systems. When the ignition switch fails, you may find ignition switch problems such as starting difficulties, electrical malfunctions. Problems should be fixed as soon as possible to avoid downtime.

How Does an Ignition Switch Work?

The ignition switch is actually a key component in connecting power and equipment systems. It controls how power is distributed to the startup, electrical, and other systems. Just like a general switch, it works by changing how circuits are connected. On many heavy equipment, the ignition switch generally has four main positions:

- OFF: Power is cut off. The machine is shut down, and everything that runs on ignition power is turned off.

- ACC (Accessory): Lets you use a few systems, like the cab light or radio, without starting the engine.

- ON: Turns on all the main electrical systems and gets the machine ready to work.

- START: Sends power to the starter motor to fire up the engine.

The ignition switch does not directly carry the high current required to start the diesel engine. It simply sends out a small current signal to trigger the relay. The relay then controls those high-load circuits, so that the electrical system can avoid being overloaded. Many modern equipment now also have security designs such as electronic immobilizers or RFID keys, which prevent the theft of the machine and ensure that only an authorized operator can start.

Symptoms of an Ignition Switch Problem

When there is a problem with the ignition switch, it can cause a variety of situations, from a minor electrical failure to the machine not firing at all. Below are a few of the most common signs of failure:

Engine Won’t Start

If you turn the key and get nothing or just a little click, the ignition switch might be the problem. It could also be the battery or starter, so check the switch too while you’re at it.

Engine Starts and Then Dies

You might manage to start your engine, only for it to stall moments later. Intermittent failure in the ignition circuit can cause your fuel pump or ignition system to lose power unexpectedly. Operators often mistake this pattern for a fuel issue.

Flickering or Dead Electrical Accessories

If cabin lights, display panel, or control screens turn off and on sporadically, you could have damaged switch contacts or loose internal connections.

Difficult Key Turn or Stuck Key

Hard-to-turn keys usually indicate internal wear in the cylinder or switch assembly. Sometimes, the key even stays stuck in the “ON” position, leaving components energized—a potential fire risk.

Sudden Stalling in Operation

Few things are more dangerous than an engine dying during heavy load. A worn ignition switch connection may lose contact over bumps or vibrations, shutting the machine down without warning. When your machine stalls at random, it’s usually not just a fuel glitch—it’s often the ignition switch acting up. If the problem comes and goes, it’ll probably get worse over time. Finding the issue early can save you from expensive downtime.

What Causes Ignition Switch Problems?

In most cases, ignition switch failure is caused by wear and tear of electrical contacts or a poor off-road environment. Below are the leading reasons:

- Wear and Tear: After thousands of starts and key turns, the ignition switch parts wear out, and the contacts don’t work as well as they used to. This can cause inconsistent performance.

- Dirt and Corrosion: Off-road machinery operates in harsh conditions, where dust, mud, and moisture are relentless. Over time, these contaminants into the connectors and interfere with voltage delivery.

- Loose Wiring or Poor Grounding: Vibration can gradually loosen connections within the switch housing or related harnesses, causing intermittent failures.

- Electrical Overload: Voltage surges or shorts caused by accessory add-ons can damage switch contacts beyond repair.

- Physical Damage or Theft Attempts: Attempts to tamper with the ignition to “hotwire” or start a machine without a key often lead to internal fractures in the switch assembly.

Knowing these causes not only helps you identify the real issue but also guides you in preventing repeat failures through regular maintenance.

What to Do If Your Ignition Switch Has Problems?

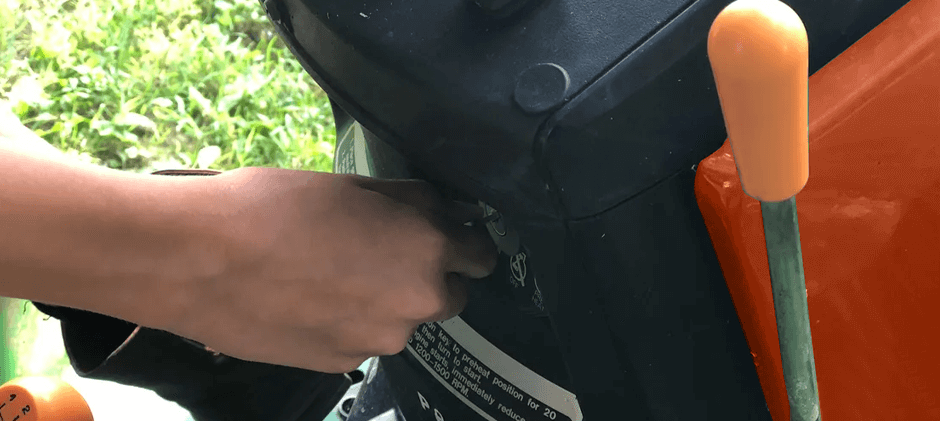

Make sure to check your equipment carefully to see if the ignition switch needs replacing. Or if professional service is required. If your key is missing or damaged, you can still replace the ignition switch without a key with the right tools and safety steps.

DIY Troubleshooting Steps

Basic electrical skills plus the right tools make it easier to spot ignition switch faults.

- Try another key. A worn key might slip instead of properly engaging the switch.

- Shift between neutral. Many machines won’t start unless the system detects it’s in neutral or fully stopped.

- Swap relays. Exchange the starter relay with another of the same type to rule it out.

- Voltage test. Use a multimeter at the ignition output terminals.

- Perform the wiggle test. Gently wiggle the key while starting; if it momentarily connects, the switch likely has internal wear.

Be cautious. When removing panels, disconnect the battery to prevent short circuits or damage to wiring. Heavy equipment usually doesn’t have airbags, but the wiring and control systems are sensitive.

Seeking Professional Help

Though DIY may be valid, in some cases, professional help is necessary. Involving complex electrical components, the ignition switch problem is complex. To be safe, have a certified mechanic do it instead. Changing the ignition switch can run you $100–$400 for the part, plus $100–$300 for labor. The price really depends on your machine and where you are. Decent aftermarket ignition switches can save some cash and still fit your equipment fine.

Bypassing the Ignition Switch Safely

If your ignition switch fails far from base, you might need a temporary workaround. Only use this in true emergencies and be very careful.

- Use a jumper wire. Connect the starter solenoid directly to the battery. Before doing this, make sure the transmission or gearbox is in neutral and all moving parts are clear. Route the wire safely away from fans, belts, or other moving components, and keep it easy to remove.

- Inline toggle for quick testing. For fast troubleshooting, you can use a toggle switch with a jumper wire as a controlled bypass. But remember—this is just a temporary solution. Using it for too long can damage circuits or bypass safety systems.

Bypassing should never replace proper repair. It’s a lifeline, not a long-term fix. When in doubt, call a technician. Don’t risk a short circuit or unwanted engine crank if you’re unsure how to do it safely.

Get New Switches

The ignition switch is a key component in starting any heavy equipment. It passes the power from the battery to the starter system, allowing the engine to rotate. Once the ignition switch is broken, the machine cannot start, and it will also affect the progress of the work. This is something FridayParts can help you solve. Our one-stop shop offers high-quality switches that are a direct fit for a wide range of brands and models, including yours!