High oil pressure is dangerous for equipment operation. When pressure gets too high all of a sudden, oil flow slows down or even gets blocked. The key parts won’t get enough lubrication. If the machine is running under heavy load for a long time, the engine temperature will shoot up faster. And the internal parts will wear out more quickly, too. Knowing what causes oil pressure helps operators spot problems early, avoiding potential engine breakdowns and costly repairs.

What Is High Oil Pressure?

If the oil pressure in the engine goes over the manufacturer’s normal range, that’s high oil pressure. Lots of people think higher pressure means better lubrication. But that’s totally wrong. Truth is, high oil pressure usually means something’s clogged up somewhere in the system. That clog makes the oil pump work overtime to crank up the pressure. The bad part? Oil can’t get to the important stuff—bearings, camshafts, turbochargers, all that.

So what’s the normal pressure range?

For most heavy-duty diesel engines in excavators and loaders: Healthy pressure is typically around 10–25 PSI (pounds per square inch) at low idle. It’s about 40–70 PSI when running at normal operating RPM under load. Note: These are just general values. The most reliable way to find the exact oil pressure range for your machine is to check the service manual.

Running the engine under excessive pressure is dangerous. It will damage seals and gaskets, and put extreme stress on the oil filter—so much so that the filter could even crack open. Eventually, insufficient oil flow caused by the blockage will accelerate component wear. In severe cases, it can even lead to total engine failure.

What are the Causes of High Oil Pressure?

When you check the high oil pressure reasons, the issue usually fits into three categories: a wrong reading, the wrong oil, or a clogged oil line. Here are the most common causes of heavy machinery:

Bad Sensor or Gauge

Before you start tearing into the engine, check the sensor first. The oil pressure sensor sends pressure info to the cab gauge—if it breaks, it might show a fake high pressure. The gauge itself could also be off. This is the best-case scenario: it’s just an electrical issue, not a mechanical problem.

Wrong Oil (Too Thick)

If the oil’s too viscous—like using thick oil when it’s cold—it won’t flow easily, so pressure spikes. This is super noticeable on cold starts, when the oil pump has to work extra hard to push the thick oil through the lines. Follow the service manual for the right oil viscosity—don’t just guess.

Stuck Relief Valve

The relief valve is supposed to bleed off extra pressure. If it gets gunked up and stays closed, pressure will shoot way too high—risking the whole lubrication system.

Clogged Oil Filter

If you skip filter changes for too long, it’ll block oil flow and create back pressure, making the pressure reading jump. Most filters have a bypass valve (to keep oil moving when clogged), but that’s a last resort—not how it’s supposed to work. It means you’re way behind on maintenance.

Clogged Oil Passages

The engine has tiny internal channels (oil passages) that feed oil to all moving parts. If you skip maintenance, sludge and gunk will block these passages. The pump will force oil through the blockage, so pressure goes up—but oil flow drops.

What Are the Signs of High Oil Pressure?

Besides the dashboard warning, high pressure usually has these clear signs:

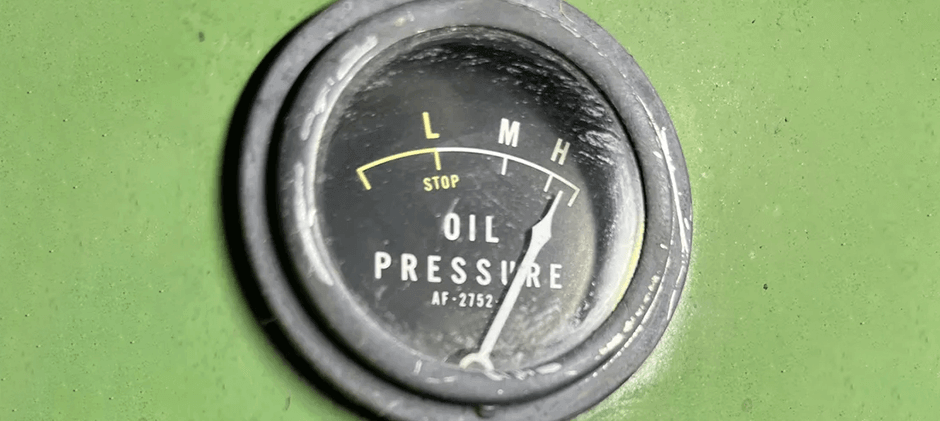

- Oil gauge stays too high: Once the engine warms up, if the pressure still sits in the high zone (even the red area), that’s not right—check it right away.

- Sudden leaks: Too much pressure can blow out seals and gaskets. You might see oil seeping or dripping around the valve cover, oil pan, or front/rear main seals.

- Oil filter bulges or breaks: In extreme cases, the pressure gets so high it warps the filter. Worse, it can burst—spilling all the oil instantly.

- Blue smoke from the exhaust: Too much pressure in the crankcase forces oil into the combustion chamber. Burning that oil makes blue smoke come out of the exhaust.

- Weird engine noises: If high pressure comes from a clogged oil line (so some parts don’t get oil), you might hear loud tapping or clattering from the top of the engine.

How Do You Fix High Oil Pressure?

Fixing it needs a logical, step-by-step approach. Start with the easiest, cheapest fixes first. Don’t run the machine until you find the root cause.

Verify thePressure Reading

Check if the gauge reading is accurate. Use a mechanical oil pressure test gauge. Remove the original sensor and install the test gauge temporarily. Start the engine, then compare the reading on the mechanical gauge with the one on the cab dashboard.

- If the mechanical gauge shows normal pressure, but the cab gauge reads high, the problem is the sensor or the gauge itself. It’s just a simple electrical issue.

- If the mechanical gauge also says pressure is too high, you’ve got a real mechanical problem. You need to move on to the next steps.

Check the Oil and Oil Filter

Drain the oil and take a look. Is the oil super thick? Did you use the wrong oil grade? Also, check the oil level on the dipstick—too much oil can sometimes cause pressure issues. Use the correct viscosity oil and a good-quality filter recommended by the machine’s manufacturer. For most heavy-duty diesel engines, 15W-40 or 10W-30 is common—but always double-check.

Inspect the Old Oil Filter

Don’t just throw it away. It holds important clues. Carefully cut open the metal case and check the pleated filter inside.

- Lots of sludge: Means poor maintenance. It could also mean the oil passages are clogged, too.

- Metal shavings: Shiny flakes (bearing material) or magnetic particles (steel) are signs of serious internal engine damage.

If you see this, high pressure is just a symptom of a bigger problem. The engine needs a full teardown.

Check the Relief Valve

If the problem’s still there after an oil change, check the relief valve. It’s usually inside the oil pump or bolted onto the engine block right next to the pump. You’ll have to take off the oil pan to get to the pump. Then clean it up and give it a good look. Does the plunger move freely? Is the spring in good shape? Most of the time, you’ll replace the whole oil pump—it comes with a new relief valve.

Get Professional Help for Clogged Oil Passages

If you’ve replaced the sensor, used the right oil, and confirmed the relief valve works, the problem is likely deeper inside the engine: clogged oil passages. Diagnosing and cleaning these passages requires taking the engine apart a lot. It’s best done by an experienced mechanic.

How to Prevent High Oil Pressure?

Keep the oil level right, like the manual says. Change the oil regularly, and use the viscosity the manufacturer recommends. When you’re running the machine, glance at the oil pressure gauge every now and then. Catching weird readings early can save you from way more expensive repairs later. If you need parts to fix high oil pressure, like oil pumps or filters, FridayParts has them. Good quality, and the prices are fair.