Heavy equipment such as excavators, loaders, forklifts and bulldozers cannot work without hydraulic systems. Whether it is lifting, steering, or the action of the boom and bucket, hydraulic fluid is used to transmit pressure and power. Hydraulic oil filters keep the system clean and running smoothly. But what is the harm of impurities in a hydraulic oil filter? And how can we extend the service life of the filter? See together.

How Do Hydraulic Oil Filters Keep Construction Equipment Running Efficiently?

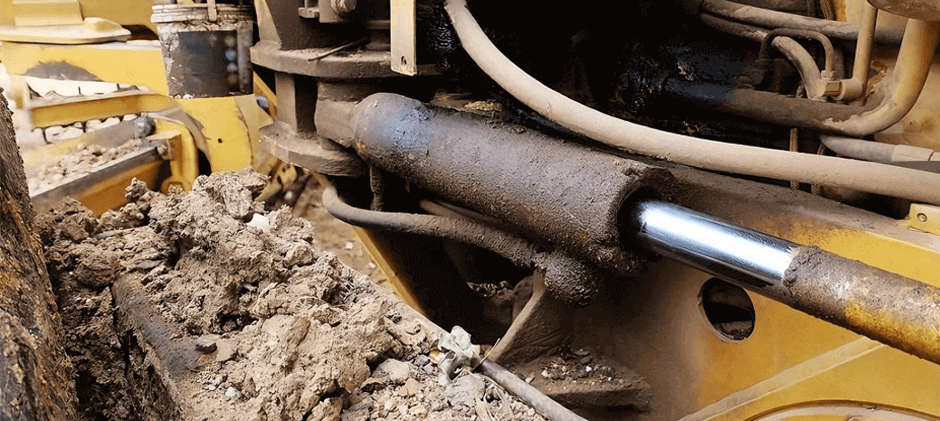

Before we talk about harm, let’s figure out what hydraulic oil filters do. In an environment such as a construction site or mine, where equipment is exposed to dust, mud and moisture for a long time, the interior of the hydraulic system also produces fine metal chips due to normal operation. The work of the hydraulic oil filter is to filter out these pollutants in time during the hydraulic oil circulation process to prevent them from damaging the pump, valve and cylinder. Specifically, a high-quality filter:

- Intercept wear particles: The filter removes fine metal chips, dust (silica) and other solid impurities. These things, like sandpaper in a liquid, slowly wear out the delicate parts of pumps and valves.

- Slowing the aging of oil: Hydraulic oil will produce sludge and paint film after being used for a long time at high temperatures. The filter can intercept these soft pollutants and prevent them from blocking the oil circuit or sticking to sensitive parts.

- Keeping the oil clean: Only when the oil is clean can the system lubricate smoothly, cool down and transmit power stably.

Without an effective hydraulic oil filter, your hydraulic system would be an open environment for self-destruction, with every cycle causing more internal damage.

What Is the Harm of Impurities in a Hydraulic Oil Filter?

Now focus. Many people think that if the filter is blocked, at most, it just doesn’t work. Actually, the problem is not that simple—when the filter is filled with impurities, it not only shuts down, but may also cause more trouble for your device. Next, we’ll see how, step by step, it triggers a chain reaction.

The Bypass Valve Opens

In each hydraulic filter, there is a small device called a bypass valve. which functions to protect the hydraulic pump from burning out because the oil cannot flow through. When the filter element is too blocked by impurities and the oil pressure is too different on both sides, the bypass valve will automatically open, allowing the oil to flow directly around the filter element.

The problem is, once in bypass, it’s actually worse. Now, the system is flowing, a pot of “dirty oil soup” mixed with metal shavings, dust, and sludge, which will rush directly into your most expensive hydraulic components, such as pumps and valves. In other words, the filter has lost its protective role and has become an accomplice in releasing pollutants.

Accelerated Wear of Components

Once the bypass valve is opened, the trouble begins. High concentrations of contaminants go directly into the system, wreaking havoc on those precision-machined parts of the equipment.

- Pumps and motors: They are the “heart” of the hydraulic system, the first to suffer. These small pieces of metal and dust will burrow into the gaps between the gears, blades or pistons, rubbing like sandpaper. Over time, the pump body was scratched and scarred, and oil began to leak inside. The machine also became noticeably weaker in power and torque.

- Control valve: The control valve is like the “brain” of the system, responsible for distributing the oil flow precisely. But “once it is stuck or worn by pollutants, various conditions will occur ——boom shaking, unsteady bucket movement, or even complete loss of control”. Not only does this affect work efficiency, but it can also pose a security risk.

- Cylinder: Contaminants can scratch the inner wall of the cylinder and can also damage the piston and seal. The result is oil leakage, loss of pressure, inability to lift up, and inability to put down. Once the oil leaks out, it not only wastes expensive hydraulic oil but can also pollute the environment.

Reduced System Performance

The operator is the first to feel the machine’s performance go down and production efficiency.

- Sluggish Cycle Times and Power Loss: Because the pump and valve are leaking oil inside, the hydraulic pressure can’t be maintained. Machines are hard when lifting heavy objects, digging hard soil, or climbing hills, with slow movements. What could have been done in half a day could now take hours more.

- System Overheating: The blocked filter element made the pump have to work harder, the oil circulation slowed down and the temperature increased. And when the bypass valve is opened, the dirty oil flows in the system at high speed, friction increases and the heat is higher. The high temperature can cause the hydraulic oil to deteriorate rapidly and the lubrication to deteriorate, eventually accelerating the aging of the system.

- Inconsistent and Unpredictable Operation: After the valve is caught by contaminants, the action becomes fast and slow, and sometimes “pauses”. If the operator wants to do some fine work, such as leveling the ground or counterloading, he will find that the machine is completely unattended, wasting time and fuel.

Shortened Lifespan of Both Oil and Equipment

Long-term use of already full of impurities hydraulic oil filters will shorten the life of the equipment and the hydraulic Oil.

- Rapid Oil Degradation: Metal particles, especially copper and iron, age the oil faster. After the oil starts to oxidize, sludge, acid and paint film will be produced, and this dirt will block the new filter element, forming a vicious cycle. The result is that hydraulic fluid is to be replaced more frequently and maintenance costs rise significantly. Actually, changing the filter element regularly is the most economical way to protect the oil and the system.

- Reduced Asset Life: A heavy piece of equipment can easily cost hundreds of thousands of dollars, and the wear and overheating of the hydraulic system cuts its life straight in half. When you find out that the pump is worn out, it will cost tens of thousands of dollars just to add labor to the parts. But all this could have been easily avoided with a filter element that cost a few hundred dollars.

How to Extend the Service Life of a Hydraulic Oil Filter?

To make the filter last longer, the most critical thing is to keep the entire hydraulic system clean. Here are some simple and practical tips to help you do just that.

Start with Clean Fluid

Many people think that it is okay to pour new oil directly into the equipment, but it is not. Dust or impurities may also be present in the new oil. It is best to filter it first with a portable oil filter truck to make sure it is clean before adding it to the machine. Also, the oil drum should be stored indoors, covered the lid covered.

Upgrade Your System’s Defenses

- Breathers: On the hydraulic tank, a normal cap may allow dust and moisture to run in. Upgrade to a high-efficiency desiccant respirator, which can filter out the fine particles in the air and also absorb moisture.

- Seals: Regularly check the seals of the piston rod of the hydraulic cylinder. A worn or damaged sealing ring can leak oil, and the piston rod retracts to carry dirt into the oil. Using good-quality seals is a good way to prevent the system from being contaminated and save money.

Perform a System Flush After Major Failures

If key components such as pumps and motors are damaged, a lot of metal debris will run into the system. Can’t just replace broken parts and cartridges. Be sure to rinse the system thoroughly, like lines, coolers, cylinders and tanks, before the machine is re-run.

Follow a Smart Replacement Schedule

The manufacturer’s maintenance cycle is only a reference. If the working environment is less dusty, the replacement cycle can be extended appropriately. However, if you are in a dusty place such as a quarry, you should shorten the filter element replacement time.

Final Thoughts on Heavy Equipment Hydraulic Oil Filter

Regularly checking and replacing hydraulic oil filters in heavy equipment is essential. Helps prevent the build-up of debris and contaminants, which can lead to costly repairs later in life. If you need to change filters for your fleet, check out FridayParts. Our growing catalog of high-quality aftermarket filters can meet your needs. Still not finding what you’re looking for? Contact our professional parts experts and get personalized help.

FAQ

What happens if the hydraulic oil filter gets too dirty?

If a hydraulic oil filter gets too dirty, it clogs. This makes the bypass valve open, letting dirty, unfiltered oil flow through the system and quickly wear out pumps, valves, and motors.

Does a dirty oil filter affect performance?

Yes, a dirty filter slows down the machine, reduces lifting and digging power, and can cause the system to overheat. It makes the equipment harder.

Can hydraulic oil contamination be repaired without replacing components?

If contamination is caught early, flushing the system and installing a new quality filter may be enough. But if abrasive wear has already damaged pumps or valves, the damage is permanent—they’ll need to be rebuilt or replaced to get the system working properly again.

Can a dirty filter cause low pressure?

Indirectly, yes. A clogged filter causes high pressure before the filter, but the bigger problem is the dirty oil it lets through when bypassed. This wears out pumps and valves, causing leaks inside the system, lowering pressure, and making the machine weak.