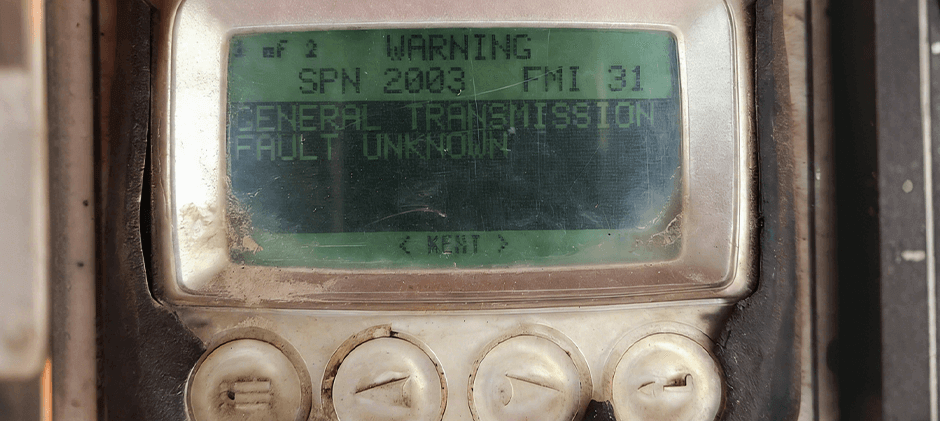

When operating off-road machinery such as bulldozers, motor graders, or articulated dump trucks, unexpected transmission faults can cause costly downtime. One of the more elusive and often misunderstood diagnostic alerts is the SPN 2003 FMI 31 code. This particular signal rarely comes with a clear explanation, yet it can paralyze an entire drivetrain system if not addressed correctly.

In this guide, we’ll break down what SPN 2003 FMI 31 truly means in plain technical terms, explore why it happens, and explain how to fix it step-by-step. By the end, you’ll understand how to restore your machine’s performance and how to select the right truck parts if replacements are necessary.

What is SPN 2003 FMI 31?

The diagnostic code SPN 2003 FMI 31 originates from the SAE J1939 standard — a communication protocol that defines how electronic control units (ECUs) share diagnostic information in heavy-duty and off-road machines.

Here’s a breakdown of the code:

| Element | Definition | Meaning |

|---|---|---|

| SPN 200 | Suspect Parameter Number | Indicates “Transmission Current Gear” signal |

| FMI 31 | Failure Mode Identifier | Condition Exists” — undefined or invalid input detected |

In practical terms, SPN 2003 FMI 31 means:

This fault doesn’t specify a single defective part — instead, it reveals that the TCM (Transmission Control Module) is receiving information that doesn’t make logical sense. The gear may not align with the expected torque, pressure readings, or output speed, prompting the ECM to disable engagement as a precaution.

Why Did SPN 2003 FMI 31 Happen?

Transmission systems in heavy machinery work under extreme load, dust, and varying electrical interference. The causes for SPN 2003 FMI 31 are often layered — sometimes electrical, sometimes mechanical. Let’s look at the root reasons.

1. Faulty Gear Position Sensor

The gear position sensor electronically communicates which gear the transmission is in. When it malfunctions, the signal may be erratic, shorted, or out of range. The TCM cannot determine if the machine is in neutral, forward, or reverse.

Field symptoms include:

- The machine refuses to engage the drive or reverse

- The gear indicator flickers or shows dashes on the monitor

- Sporadic shifting behavior

Why it matters:

An inaccurate signal prevents TCM logic validation — therefore, the system triggers SPN 2003 FMI 31 and often locks the transmission into neutral to protect internal gears.

2. CAN Bus Communication Delay or Loss

In off-road machinery, several modules — like the ECU, hydraulic controller, and TCM — communicate over a CAN (Controller Area Network) line. A temporary delay caused by corrosion, vibration, or damaged wiring can trigger undefined gear readings.

Common causes:

- Moisture or corrosion in harness connectors

- Loose grounding points

- Unstable voltage supply to the TCM

- Excessive electromagnetic interference from nearby systems

3. Internal Software or Logic Glitch in the TCM

Sometimes SPN 2003 FMI 31 may appear after a power supply interruption or a failed ECU boot sequence. During initialization, gear logic is compared to clutch pressure and output speed. If any reading mismatches, the TCM logs this code.

A control module reset or a simple re-flash often resolves such issues, provided there’s no mechanical damage.

4. Faulty Speed or Ratio Sensor Data

If the input or output shaft sensor returns inconsistent speed data, the TCM cannot validate gear ratios. The mismatch between input rotation and output torque causes a logical contradiction within the control logic — another reason SPN 2003 FMI 31 may appear.

5. Real Mechanical Shifting Problem

Although this is the least common cause, worn clutch packs or faulty shift solenoids can cause an actual gear engagement failure that the TCM interprets as a logic fault. In these cases, the root cause lies in the transmission’s mechanical hydraulics, not the electrical side.

Overview Table — Common Causes

| Category | Component / Source | Result | Diagnostic Action |

|---|---|---|---|

| Electrical | Gear position sensor or switch | Undefined gear position | Test sensor voltage ranges |

| Network | CAN bus wiring or connectors | Incomplete communication | Inspect and clean terminal pins |

| Software | TCM calibration fault | Temporary control lock | Re-flash or reset the control module |

| Sensor Input | Output or input speed sensors | Gear ratio conflict | Cross-check signal waveforms |

| Mechanical | Shift solenoids, clutch discs | Physical slipping | Inspect and replace components |

How to Fix SPN 2003 FMI 31 Code?

Fixing SPN 2003 FMI 31 involves a mix of electronic verification and mechanical inspection. The steps below help isolate the cause efficiently.

Step 1: Scan All Active and Inactive Codes

Before performing physical checks, connect diagnostic equipment compatible with J1939 (for example, PowerView or similar tools). Verify if additional codes like SPN 191 FMI 2 (Output Speed Signal Error) or SPN 639 FMI 9 (Communication Lost) are present.

If secondary codes exist, resolve them first — they often cascade into 2003/31.

Step 2: Check Power Supply and Ground Integrity

- Measure TCM power input voltage. It should remain consistent with battery voltage.

- Perform a voltage drop test on the ground line under load (should stay below 0.1V).

- Clean and tighten all ground contacts.

A weak ground or spike can easily confuse the module logic, causing undefined conditions.

Step 3: Inspect Wiring and Connectors

Off-road conditions mean mud, vibration, and temperature extremes — the ideal environment for intermittent faults.

Inspection checklist:

- Disconnect and examine the TCM, gear sensor, and CAN connectors for signs of corrosion.

- Check wire insulation for cracks and exposure.

- Clean connectors using approved electrical contact spray.

After cleaning, reseal connectors with dielectric grease to prevent future moisture buildup.

Step 4: Test Gear Position Sensor

Manually measure sensor output voltage between each selector position using a digital multimeter. There should be a steady voltage change between gears (e.g., 0.5V at Neutral to 2.5V at Forward).

If readings remain static or spike randomly, replace the sensor immediately.

Step 5: Run a Module Self-Test or Clutch Calibration

Most transmission controllers allow recalibration of clutch and solenoid parameters. Perform a relearn cycle through your diagnostic tool to reestablish proper logic mapping.

This procedure resets all internal reference points and often clears SPN 2003 FMI 31 permanently.

Step 6: Replace or Update Transmission Components if Needed

If repeated tests confirm sensor damage or mechanical wear, replacement is the most reliable path forward. Proper replacement restores signal stability and prevents intermittent fault recurrence.

You can easily source replacement clutch discs, bearings, gear hubs, and transmission components for multiple heavy equipment brands through FridayParts’s truck parts section — each part is tested for precision and durability in heavy-duty conditions.

Preventive Measures

Avoiding SPN 2003 FMI 31 in the future depends on proactive habits:

- Inspect wiring looms quarterly, especially near hot areas of the powertrain.

- Keep transmission connectors sealed with non-conductive grease.

- Replace worn clutch components during regular maintenance intervals.

- Avoid welding or jump-starting equipment without disconnecting ECUs.

- Verify correct grounding before the seasonal operation starts.

Regular inspection is cheaper than transmission failure. Preventive diagnostics can save thousands in downtime costs.

Related Transmission Parts for Maintenance

Below are some top-selling transmission parts for heavy machinery from FridayParts that help sustain consistent drivetrain performance:

| Part | For / Compatibility | Price (USD) |

|---|---|---|

| Friction Clutch Disc AT339922 | John Deere 210K, 310K, 410L Loaders | $14.59 |

| Clutch Disk 332/F6082 | JCB Wheel Loader 427 | $78.40 |

| Ball Bearing GW211PPB20 | John Deere 310–670 and 2720–2660VT | $34.26 |

| Universal Joint 144465A1 | CASE 5120–590SM Loaders | $22.81 |

| Roller Bearing 337607A1 | CASE Forklifts 586G/H | $72.00 |

These parts and many others ensure smoother transmission operation and support proactive fault prevention.

Conclusion

The SPN 2003 FMI 31 code might seem obscure, but it’s often a symptom of sensor miscommunication or electrical interference rather than a total transmission failure. Addressing it methodically — checking grounds, scanning, recalibrating the TCM, and replacing faulty sensors — ensures your off-road machine’s drivetrain stays reliable. For cost-effective and durable replacements, explore FridayParts’ wide inventory of truck parts designed for multiple heavy machinery models, ready to get your equipment back to full power quickly.