When P203F Cummins shows up on an off-road machine, the problem is rarely “mystery emissions.” It’s usually something practical we can verify: the DEF (diesel exhaust fluid) level really is low, the level reading is wrong, or the signal can’t reach the control module due to wiring/connector issues. In this guide, we’ll explain what the code means, why it happens on heavy equipment, what symptoms to expect (including derate/no-start), and how we fix it step by step without swapping parts blindly.

Key Takeaway

P203F Cummins points to a DEF/reductant level too low condition—either the tank is actually low, or the machine thinks it is because of a bad level sensor, wiring/connection trouble, or DEF quality/contamination issues. The fastest path is: verify DEF level/quality → check connectors and harness routing → confirm sensor readings with scan data → repair the root cause, then clear the fault and confirm the inducement resets.

What Does the P203F Code Mean?

On Cummins-powered off-road machinery with SCR aftertreatment, P203F is commonly used to indicate “Reductant (DEF) Level Too Low.” DEF is stored in a tank and injected into the exhaust stream upstream of the SCR catalyst to reduce NOx emissions. The control module monitors the DEF level signal (and often quality/temperature signals depending on the setup). If the level signal indicates “too low” for long enough, or falls outside expected behavior, it logs P203F Cummins and may start an inducement strategy.

What that means in the yard or on the jobsite:

- The machine may warn the operator first.

- Then it may derate power, limit speed, or restrict RPM.

- In some configurations, it can escalate to no-start after key cycles if the condition isn’t corrected.

A key point for off-road owners: P203F can appear even when the DEF tank looks full if the level sensor is failing or the wiring has high resistance/corrosion. So we don’t want to assume it’s just “add DEF” without checking scan data and wiring integrity.

Why does the P203F Code Happen?

On heavy equipment, most P203F root causes fall into a few repeat patterns driven by vibration, moisture, temperature swings, and long service intervals.

1) DEF level is truly low (or the tank is not filling as expected)

This sounds basic, but it’s common in fleet operations:

- DEF gets topped off less often than diesel.

- Tanks can be hard to visually gauge.

- Some tanks have shapes that make “looks full” misleading on slopes.

What we do: confirm the level on flat ground (per OEM procedure), and verify the dash/scan tool level reading changes appropriately after filling.

2) Failed or drifting DEF level sensor (false “low”)

Level sensors can fail electrically or mechanically. Common patterns:

- stuck reading (never changes)

- intermittent drops on bumps

- wrong reading after temperature changes

If you see P203F with a tank that’s clearly not empty, the level sensor moves up the suspect list quickly.

Related parts note: DEF tank assemblies vary by machine, but level sensing is a common failure point in off-road aftertreatment systems—especially where vibration and washdown are routine.

3) Wiring and connection faults (very common on off-road machines)

In real-world equipment conditions, wiring problems cause “comes and goes” faults:

- Water intrusion into connectors after pressure washing or rain/snow

- Pin corrosion/oxidation

- Rubbed-through insulation at clamps, frame edges, or near the tank

- Broken ground or a conductor cracked inside the insulation

This is why we always inspect the harness and connectors before we condemn expensive components.

If you need replacement harnesses/cables for heavy equipment repairs, this category is purpose-built for uptime fixes: wiring and connections.

4) DEF quality/contamination problems that lead to confusing warnings

While P203F is a “level too low” code, bad DEF can still contribute indirectly:

- Contaminated DEF can crystallize and create tank/sender issues

- The wrong fluid can damage sensors or cause control logic conflicts

- Old DEF or poor storage can cause system faults that stack with level warnings

Practical rule: If DEF looks cloudy, has debris, or smells off (DEF should be clear and clean), we treat it as suspect and correct it before deeper electrical work.

5) Control module logic issues (less common, but real)

Software or module issues can happen, but in off-road equipment, we treat this as a last step after we verifythe level, sensor, and wiring. Module replacement or programming is costly and machine-specific.

What are the Common Symptoms of the P203F Code?

Symptoms vary by machine and how far the inducement has progressed. Here’s what we typically see on off-road equipment:

- Check engine light / MIL or an aftertreatment warning lamp

- DEF level warning on the cluster/display

- Derate: reduced power, limited RPM, slow travel/implement response

- Countdown or inducement messages (on some displays)

- No-start risk if ignored long enough (machine-dependent)

- Sometimes the machine “runs fine” at first, which is why operators keep working until the derate hits at the worst time.

Quick Reference Table

| Likely Cause | What We Check First | Typical Fix |

|---|---|---|

| DEF actually low | DEF level per OEM procedure; scan tool level % | Fill with correct DEF; verify level signal updates |

| DEF level sensor fault | Live data stuck/erratic; sensor connector condition | Replace the sensor/tank sender as applicable |

| Harness/connector issue | Corrosion, loose pins, rubbed insulation, poor ground | Repair/replace harness/connector; secure routing |

| DEF contamination/wrong fluid | Visual inspection; service history; tank condition | Drain/flush per OEM guidance; refill with correct DEF |

| Module/software issue | Only after all the above pass | OEM-level diagnostics, update, or module repair |

How to Fix the P203F Code?

We fix P203F Cummins fastest when we follow a controlled order. Here’s a field-proven workflow for off-road machinery owners and techs.

1) Confirm the code and capture freeze-frame/live data

- Read all active and stored DTCs (P203F may be accompanied by other DEF/SCR codes).

- Record DEF level %, voltage readings, and any tank temperature signals if available.

- Note whether the issue is intermittent (bumps, wet weather) or constant.

Why this matters: If live data shows the level stuck at 0% or wildly jumping, we stop guessing and move to sensor/wiring checks.

2) Verify DEF level the right way

- Park level, follow the machine’s checking procedure.

- Fill with the correct DEF from a clean source.

- Re-check the scan tool DEF level % and see if it changes.

If DEF level is truly low, filling may resolve the warning—but we still confirm that the level reading is believable afterward.

3) Inspect the connector and harness at the DEF tank

This is where off-road machines often fail:

- Disconnect and inspect for green/white corrosion

- Check for bent pins, loose fit, and cracked connector housings

- Look for rub points along the harness run to the frame/aftertreatment area

- Verify ground integrity under load (a “good” ground with no load can still fail under current)

If the connector is compromised, replacing the assembly is often more reliable than repeated splicing. For application-specific repair parts, start here: wiring and connections.

4) Test the level sensor circuit (don’t just replace parts)

Depending on the machine and sensor type, we typically:

- Check the reference voltage and ground at the sensor connector

- Check the signal return continuity back to the module

- Perform a wiggle test while watching live data (to catch intermittent breaks)

- Compare sensor reading to known tank level (after fill)

If the circuit tests good but the signal is wrong, the sensor becomes the primary suspect.

If you’re sourcing heavy equipment sensors, including DEF/coolant/oil level sensing options, browse: level-sensor.

5) Address DEF quality/contamination if evidence points there

If we find contamination, we correct it decisively:

- Drain/clean tank per OEM guidance

- Replace filters/screens if equipped

- Refill with fresh DEF from sealed containers

- Clear codes and verify stable readings

Note: Avoid improvised chemicals or “DEF hacks.” Off-road SCR systems are sensitive, and quick fixes often cause bigger downstream failures.

6) Clear the code and confirm the inducement resets

After repairs:

- Clear DTCs

- Key cycle and run the machine

- Confirm DEF level live data is stable

- Confirm warnings/derate behavior is gone (some systems require a specific drive/run cycle)

If P203F returns immediately with a confirmed good level and good wiring/sensor readings, then we escalate to OEM-level diagnostics for module logic or calibration concerns.

Conclusion

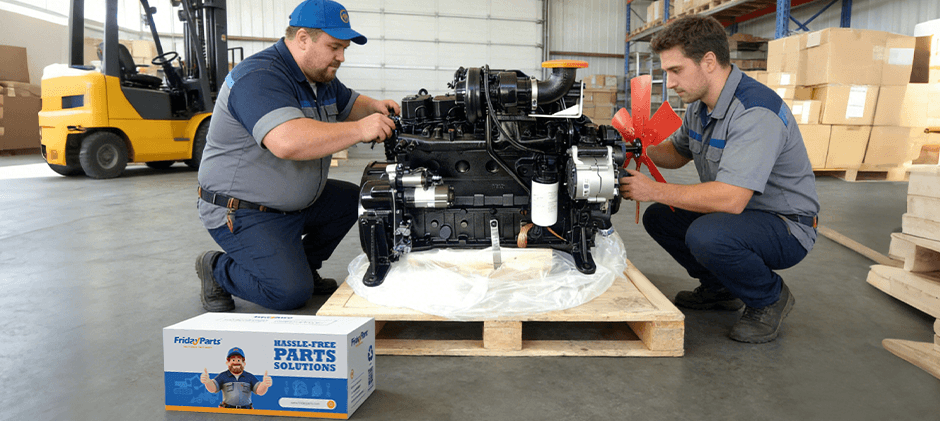

P203F Cummins is usually a solvable DEF level signal problem: low DEF, a bad level sensor, or wiring/connectors that can’t hold a clean signal in harsh jobsite conditions. When we verify level and scan data first, then inspect wiring before replacing parts, we avoid repeat derates and surprise no-start events. If you need reliable aftermarket replacements, FridayParts supports off-road machinery owners with high-quality products at affordable prices, a vast inventory, and wide compatibility across many heavy equipment brands.