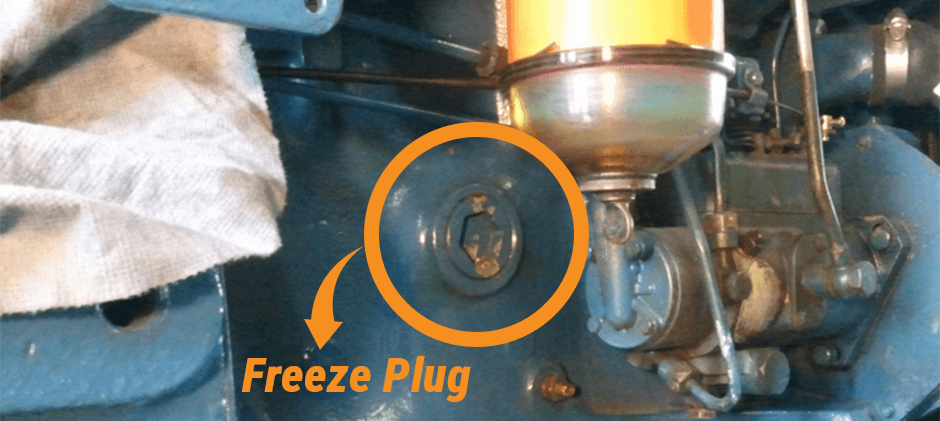

When building an engine, casting is how you get the mold and the right shape. Freeze plugs for the engine block are used to seal up the holes left from the manufacturing process—these holes are made to let out the casting sand. They’re metal discs that sit inside the engine block. Leaving these holes open isn’t safe, and most of them are in the cooling system, so you need freeze plugs to seal them off.

What Is a Freeze Plug?

A freeze plug is a small metal disc that’s pressed into place. It seals holes in the engine block or cylinder head. Most diesel engines have several of these plugs. They’re usually made of steel, brass or stainless steel. And they’re a must for keeping coolant sealed inside the engine’s cooling passages.

Techs might call them other names—core plugs, frost plugs or expansion plugs. It’s all the same part. They’re simple in design, but their job is super important. If a freeze plug fails, you’ll lose coolant fast. The engine will overheat, and that’ll cause expensive damage if you don’t fix it right away.

What Are Freeze Plugs For?

A lot of people get the name “freeze plug” wrong. Most folks think these plugs pop out if the engine’s coolant freezes, acting like a release valve to stop the expanding ice from cracking the heavy iron engine block. Sure, a plug might pop out every now and then when this happens, but that’s not what it’s made for—never count on it to save your engine. Even with the plugs in place, frozen coolant can still create enough pressure to crack the block.

The real reason these plugs exist ties back to how engines are made. Engine blocks are cast by pouring molten metal into a sand mold—this is called sand casting. To make the tiny internal channels that coolant flows through, a sand core is put inside the main mold. Once the metal cools and hardens, that sand has to be removed. The holes where freeze plugs are installed are just the factory’s way to break up and rinse out all that casting sand.

Once the engine block is clean, those holes are sealed with core plugs to make the cooling system 100% watertight. So their main job isn’t to protect against freezing—it’s to seal the engine up for good.

Signs of a Faulty Freeze Plug

A bad freeze plug will almost always let you know it’s failing with a coolant leak. Since your equipment works in harsh conditions, it’s key to tell a real leak apart from just mud or water.

- Coolant drips: Check the ground for green, pink or yellow puddles, or fluid dripping from the engine block.

- A sweet smell: Engine coolant has ethylene glycol in it. It gives off a strong sweet smell when it gets hot or burns on the hot engine block. If you smell this near the engine, it’s a sure sign of a leak.

- Engine overheating: A leaking freeze plug makes the coolant level drop. Without enough coolant to absorb and carry away heat, the engine temp will shoot up fast. An overheating engine can cause warped cylinder heads, or even a total seizure.

- Low coolant level all the time: Are you refilling the coolant tank way more often than usual? If you can’t find a leak in the hoses or radiator, a hidden, rusted freeze plug is almost certainly the issue. It might be a slow leak that only shows up when the engine’s hot and under pressure.

What Causes Freeze Plug Problems?

Freeze plug failure usually happens faster because of tough job site conditions and how you maintain the equipment.

Corrosion

Freeze plugs can rust on the outside and inside. Outside rust forms when mud or water sits on the plug, or when high-pressure washing forces water behind it. Inside rust is more common: old coolant loses its rust-fighting properties over time, turns acidic, and eats through the metal. Since freeze plugs are thin, they’re usually the first to start leaking small amounts.

Electrolysis

It happens when different metals in the cooling system—like the iron block, aluminum heads and brass plugs—create a tiny electric current through the coolant. This current quickly eats away at the softest metal in the system, which is almost always the freeze plug. Old coolant or a bad ground connection on the machine makes this way worse.

Physical Damage

This is also common on busy job sites. A rock, branch or other debris thrown up by the tracks can hit an exposed freeze plug, damage it, and cause a leak.

How to Cope With Freeze Plug Failure?

If you find a leaking freeze plug, don’t reach for a temporary leak stopper product. It might feel like a quick fix to finish the workday, but this stuff does way more harm than good in an engine. They work by hardening when they touch air, but they’ll also clog the tiny passages in your radiator, oil cooler and heater core. That’ll lead to way bigger overheating issues later on.

The only permanent fix is to replace the freeze plug. How hard this job is varies a lot. If the leaking plug is in an easy spot on the side of the engine, a tech can usually swap it out in an hour or two. But some freeze plugs are in tight spaces. On an excavator, a plug on the back of the engine might mean taking out the transmission or the main hydraulic pump. In the worst case, you even have to pull the whole engine out of the machine.

This is why prevention is so important. Always use long-life coolant that the machine’s maker recommends, and change it when the service schedule says to.

What to Consider When Buying Freeze Plugs?

Material

- Brass: Great at fighting corrosion, but it’s a softer metal.

- Steel: Strong and long-lasting, but it’ll rust if the protective coating gets scratched when you install it.

- Stainless steel: The top pick—it’s strong and corrosion-resistant, so it lasts the longest.

Size

Freeze plugs aren’t one-size-fits-all. They’re made for a specific engine make and model. Even a tiny mismatch can cause a bad seal or damage the engine block. Always use the exact part number for your engine.

Quality

A cheap plug made with bad metal or shoddy manufacturing is a risk. It’s smart to buy replacement plugs from a trusted aftermarket supplier, and it won’t cost as much as the dealer’s price.

Do Engine Block Drain Plugs and Freeze Plugs Serve the Same Purpose?

Not at all, they do totally different jobs. Drain plugs are for service work; freeze plugs are just for sealing holes.

A freeze plug (or core plug) is a press-fit seal for the holes left from manufacturing, and it’s meant to stay put for good. If you try to unscrew or pry it out the wrong way, you’ll damage the plug, and probably the engine block too.

An engine block drain plug is a threaded plug, usually with a hex or square head. It’s at the lowest spot of the engine’s coolant jacket, and it’s made to be removed on purpose—so you can drain all the coolant out when doing maintenance.

In Conclusion

Most freeze plugs last a really long time and usually don’t need replacing. But if you don’t maintain your cooling system well, rust sets in faster—and they can go bad in just a few years. Cold weather is tough on them, too, especially if the coolant freezes. And the engine overheating a lot will also make them fail early. Got a freeze plug problem? Find the right cooling system parts for your equipment at FridayParts.