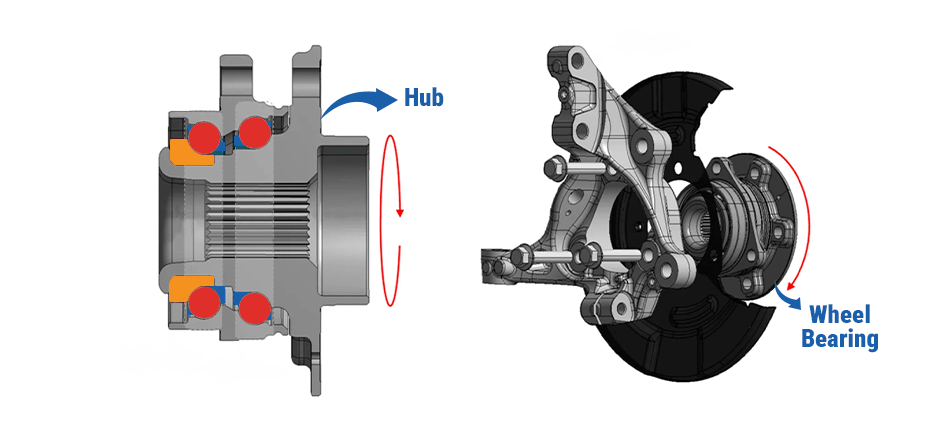

A new grinding or roaring noise from your excavator or loader is not “normal.” It can be a warning from the wheel bearing. A wheel bearing helps the wheel turn smoothly while carrying a heavy weight. If it fails and you keep working, you can damage the hub, axle parts, and brakes—and you can put the operator in danger. This guide explains the signs to watch for, what can happen if you ignore them, and what to do next to stay safe and reduce downtime.

4 Telltale Signs of a Failing Wheel Bearing

A wheel bearing usually gives warning signs before it fails. Your job is to notice them during daily checks and while operating.

1. What Is That Unusual Noise?

Unusual noise is the most common sign. The sound often gets louder as you drive faster. It may also change when you turn. Listen for:

- Roaring or Humming: A deep, steady sound, like loud tires, but it does not go away on different ground.

- Grinding or Growling: A harsh metal sound that can mean the rollers inside are damaged.

- Clicking or Popping: Short, sharp sounds, often easier to hear when turning or hitting bumps.

Simple tip: If the noise changes when you turn left or right, a bearing may be the cause.

2. Why Does the Wheel Feel Loose?

A bad bearing can create extra space inside the wheel hub. This can make the wheel feel loose or wobbly. This is dangerous and can mean the bearing is close to failing.

To check as safely as possible:

- Park on level ground and shut the machine off.

- Block/secure the machine so it can’t roll.

- Jack up the wheel only if you have the right lifting tools and a safe method for your machine.

- Hold the tire at 12 o’clock and 6 o’clock and rock it in and out.

- Feel and listen for movement (“play”) or clunking. Any clear movement is a red flag.

Clear rule: A wheel should not wobble. If it does, stop work and inspect.

3. Why Is the Hub So Hot?

A failing bearing creates friction, and friction makes heat. After running the machine, carefully check the hub area.

One hub much hotter than the others is a warning sign. For a safer check, use an infrared temperature gun instead of touching the hub.

Simple comparison helps: Check all hubs. The odd one out is the problem spot.

4. What Is That Leaking From the Wheel?

A wheel bearing uses grease (or oil, depending on design) and seals to keep dirt and water out. When a seal is damaged, grease or oil can leak.

Look for:

- Grease/oil on the inside of the rim

- Grease/oil near the hub

- Grease/oil on brake parts

Why this matters: A leak lets dirt and water in, which can ruin the bearing quickly.

What Happens If You Ignore the Signs?

Ignoring a bad wheel bearing almost always leads to bigger damage. It is not a problem to “wait and see.”

“A failing wheel bearing is not a risk; it’s a countdown. The question isn’t if it will fail, but when.”

1. Catastrophic Failure: The Wheel Can Detach

The worst case is the wheel assembly coming off during operation. On heavy equipment, this can cause a loss of control or even a rollover, especially on rough ground or slopes.

Simple truth: A detached wheel can turn into a serious accident.

2. Collateral Damage: A Chain Reaction of Repairs

When a bearing breaks apart, it can damage nearby parts. This often includes the hub, spindle, seals, brake parts, and axle components.

What could be a bearing job can become a full wheel-end rebuild. That means more downtime and higher costs.

3. Loss of Control: A Major Safety Hazard

Even before full failure, a loose wheel can make steering feel strange and the machine less stable. This is more dangerous when carrying heavy loads.

Clear warning: If the machine feels unstable, stop and check it.

3 Immediate Steps to Take

If you suspect wheel bearing trouble, act right away. Do not keep pushing the machine.

Step 1: Stop Operations Immediately

Stop work as soon as you can do so safely. Park on firm, level ground away from traffic and hazards.

Priority: Protect the operator and anyone nearby.

Step 2: Perform a Safe Inspection

Once the machine is secured, check the key signs:

- Noise that changes with speed or turning

- Wheel play (only if you can lift it safely)

- One hub is running hotter than the others

- Grease or oil leaks around the hub/brakes

Good notes help: Write down which wheel, what you heard, and what you saw. This repairs faster.

Step 3: Contact a Professional for Repair

Wheel bearing work on heavy equipment often needs special tools and correct settings for preload and torque. A wrong installation can cause another quick failure.

Simple guidance: If you don’t have the right tools and specs, don’t guess—get qualified help.

3 Ways to Extend Wheel Bearing Life

Good habits can help wheel bearings last longer and reduce surprise breakdowns.

1. Prioritize Proper Lubrication

Use the correct grease or oil recommended by the manufacturer. Follow service intervals and use clean tools.

Important: Do not mix greases unless you know they are compatible.

2. Conduct Regular Inspections

Add quick checks to your walk-around:

- Look for fresh leaks

- Listen for new noises

- Feel for abnormal heat (use a temp gun if possible)

- Check for wheel play when safe and allowed by your maintenance procedure

Small checks can prevent big repairs.

3. Promote Smooth Operation

Operator habits matter. Hard impacts and shock loads can shorten bearing life.

Try to avoid:

- Slamming a loaded bucket down

- Hitting curbs/rocks at speed

- Fast travel over rough ground with heavy loads

Simple idea: Smooth driving equals less stress on bearings.

Final Thoughts

A wheel bearing often warns you before it fails. If you hear new roaring or grinding, feel wheel wobble, notice heat, or see grease leaking, stop and check it. Catching the problem early helps keep the operator safe and reduces damage and downtime.

If a replacement is needed, choose a correct-fit, durable bearing from a reliable supplier like FridayParts and follow the proper install specs for your machine.