Key Takeaways

- Stop immediately when the steering wheel light appears.

- Start with simple hydraulic checks before electrical diagnostics.

- Use measured testing, not guesswork.

- Perform a SAS reset after sensor replacement.

- Choose quality parts to prevent repeat failures.

A glowing steering wheel light on your heavy equipment’s dashboard signals a critical safety issue. Never ignore it. This guide provides a step-by-step approach to help you accurately diagnose the problem, whether it’s hydraulic, electronic, or mechanical, so you can handle the repair with confidence.

Safety First

As soon as the light appears:

- Stop the machine on level ground.

- Lower all attachments.

- Shut down the engine.

- Keep people clear.

Never keep operating when the steering assist system might be compromised.

What The Steering Wheel Light Means

The steering wheel light is just one of many important symbols on your dashboard. For a complete overview, you might find our Tractor Dashboard Symbols and Meanings helpful.

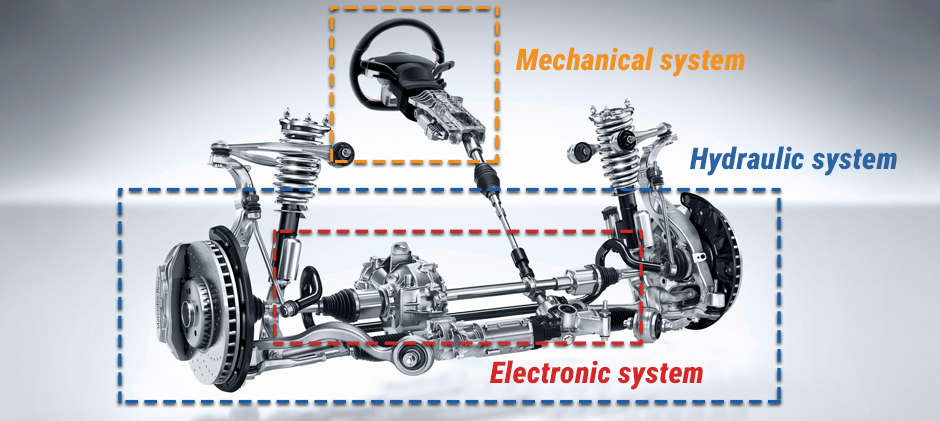

- Hydraulic system (the muscle) – provides steering power. To understand this system better, see our guide on How Does a Hydraulic Pump Work in Heavy Equipment?.

- Electronic system (the control) – detects steering angle and regulates assist.

- Mechanical system (the structure) – connects the motion physically.

A fault in any of these will trigger the light. A frequent culprit is a Steering Angle Sensor (SAS) fault, which occurs when the ECU loses the accurate steering position signal.

Common Steering System Faults

Hydraulic System Faults

| Fault | Description | Typical Symptoms | Diagnosis |

|---|---|---|---|

| Low or Contaminated Oil | Oil level too low, dirty, or wrong type reduces pressure. | Heavy or noisy steering, delayed response. | Check oil level, cleanliness, and smell. |

| Pump Failure | A worn pump or damaged belt prevents pressure build‑up. | Sudden or gradual loss of assist, noise varies with RPM. | Inspect drive belt; measure pump outlet pressure. |

| Hose or Fitting Leak | Loose, cracked, or blocked hose reduces flow. | Visible leaks, soft or fading steering. | Visual check for oil traces or bulges. |

| Control Valve Issue | A sticking spool or seal leakage affects oil flow. | Dead zone, jerky movement. | Perform a pressure check at valve ports. |

| Cylinder Internal Leak | A worn piston seal allows internal oil bypass. | Weak assist, drifting wheels. | Pressure test; check for external leaks. |

Electronic System Faults (Except SAS)

| Fault | Description | Typical Symptoms | Diagnosis |

|---|---|---|---|

| Wiring or Connector Fault | Broken or corroded wires cause signal loss. | Intermittent warning, light flickers on bumps. | Use a multimeter; check continuity and move the harness to test stability. |

| ECU Fault | Internal failure prevents control or communication. | No assist, steady warning light, multiple trouble codes. | Confirm ECU power and ground; test communication via scan tool. For an example of code diagnostics, see our Kubota Error Codes Guide. |

| Power or Ground Problem | Low voltage, bad ground, or fuse failure. | Dim lights, random system errors. | Measure battery/charging voltage, inspect all related fuses and grounds. This can also trigger other warnings, like the one explained in What Does Battery Light on Dash Mean?. |

Mechanical System Faults

| Fault | Description | Typical Symptoms | Diagnosis |

|---|---|---|---|

| Linkage Wear (Tie Rods, Ball Joints, Kingpins) | Excess clearance due to wear or loose parts. | Steering play, knocking noise, uneven tire wear. | Lift front axle; move wheels to check looseness. |

How to Identify the Problem?

- Observe the Warning – Note if the light stays on or flashes, and how the wheel feels.

- Check the Basics – Inspect the hydraulic oil, belt, and leaks.

- Use a Scan Tool – Read the Diagnostic Trouble Codes (DTCs).

- Inspect Wiring – Measure voltage, ground, and continuity; wiggle the harness to confirm.

- Confirm and Replace SAS Only if Faulty – Swap sensors only after testing wiring and voltage.

- Test Hydraulic Pressure – If no electronic faults exist but steering is heavy, check pump pressure.

- Repair and Validate – Replace defective parts, clear codes, and perform a test drive.

Steering Angle Sensor and SAS Reset Meaning

The steering angle sensor measures the direction and amount of wheel rotation. After replacement, it requires a SAS reset, which recalibrates its zero position.

Skipping calibration may cause:

- Warning light remaining on

- Uneven or erratic assist

- False traction or stability warnings

Use a diagnostic tool to complete the calibration after every SAS replacement, removal, or battery reset.

Final System Check

After any repair:

- Clear all DTCs.

- Calibrate (SAS reset).

- Test steering in both directions at low speed.

- Reinspect for leaks or looseness.

Only return the machine to service after confirming a normal response and no warning lights.

Wrapping Up

When confirmed faulty, replace the steering wheel sensor with a high‑quality part. Avoid low‑grade replacements that can cause repeat faults.

FridayParts provides exact‑fit steering parts for major heavy‑equipment brands, designed to meet OEM standards and tested for performance. Visit today, enjoy a 1-year warranty and 90-day return & change to bring your equipment back to its top condition!