Have you noticed rust on the bottom edge of your vehicle (just below the door)? Don’t worry, it’s not your own trouble. Many car owners experience this headache, and the main blame to a key component—the rocker panel. What are rocker panels? Why it important for vehicle safety? What to do about those annoying rusts? You’re in the right place. Next, we will talk about what you want to know about rocker panels.

What Are Rocker Panels?

The rocker Panels, sometimes just called rockers, are the lower positions on both sides of the body. It is the long steel plate between the front wheels and the rear wheels, directly below the door. It looks like a simple exterior piece, but it is a very important part of the vehicle’s structure.

On most modern sedans and SUVs with a “carrier-bodied ”unibody design, the sill panels are welded directly to the body frame. In this structure, it is one of the load-bearing parts and has a great influence on the overall strength of the body. It connects the front and rear parts of the bodywork together, preventing the vehicle from twisting or sinking in the middle.

And on some pickup trucks or old SUVs, the design is “body-on-frame”, and the sill plate is an important part of the cockpit structure, which can enhance the rigidity of the body and also protect the body to a certain extent. Crew safety. Regardless of the construction, the sill plate is an indispensable key component in maintaining the strength of the body.

Where is the Rocker Panel Located?

Finding the rocker panels is simple. Open any door and look down at the position under the door. Along the bottom of the door, the metal strip on the outside of the floor of the compartment is the upper edge of the rocker panel.

The rocker panel is the long metal part between the front and rear wheels and under the door. Depending on the model or configuration, some of it will be completely exposed, while plastic trim panels, side skirts, or footrests will partially cover others. Whatever, their location is easy to roads, gravel, water, and salt. So, it tends to rust.

What Do Rocker Panels Do?

The rocker panel’s main functions are supporting the structure and protecting the body. The rocker panel is an important part of the strength of the body. It connects the front and rear structures of the vehicle to help spread the force when driving, turning, or in the event of a collision. The strong and complete rocker panel maintains the shape of the carriage in a collision and plays a key role in occupant safety.

Secondly, the rocker panel also acts as a protection. Because of its low position, it often withstands the impact of stones, mud, and debris thrown from the tires, thus protecting the rear frame and floor from damage. But it is also because of long exposure to this environment that it is more susceptible to wear or rust. Think of rocker panels as the backbone of your vehicle’s sides. They distribute impact forces and prevent the central part of the vehicle from collapsing, making them one of the most important passive safety features you have.

Why Do Rocker Panels Rust So Easily?

If any part of the body must be rust, it’s the rocker panels. This is not a design flaw, but a necessity caused by its location and structure. Several factors work together to make it susceptible to corrosion.

- Constant Exposure to Elements: Rocker panels are on the front line, next to water, mud, snow, and dirt on the road every day. Every time the car goes through a puddle or runs on a slippery road, the tires throw the water over this area.

- Trapped Moisture and Poor Drainage: Draining the standing water is a common problem. Many of the rocker panels are hollow box-like structures with several small holes underneath for drainage. Over time, these holes tend to become clogged with mud and debris. In this way, the water and the salt on the road are trapped inside, slowly corroding against the metal and rusting from the inside out. By the time rust bubbles appear outside, the inside is actually quite damaged.

- The Corrosive Effect of Road Salt: For those who live in places where snow often falls, snowmelt salt on the road is the enemy to the car. The salt will accelerate the rate at which the metal will rust, corroding particularly quickly. Rocker panels are often splashed with salt-laden mud and water, and naturally, they become one of the most problematic places.

- Damage to Protective Coatings: The rocker panels can block stones on the road, but the flying gravel can also slowly damage the bottom of the vehicle. They can leave small cracks or scratches on the paint and protective layer. Once the metal is exposed in these small wounds, air and moisture can go in, and from there, the rust begins to spread.

Types of Rocker Panels

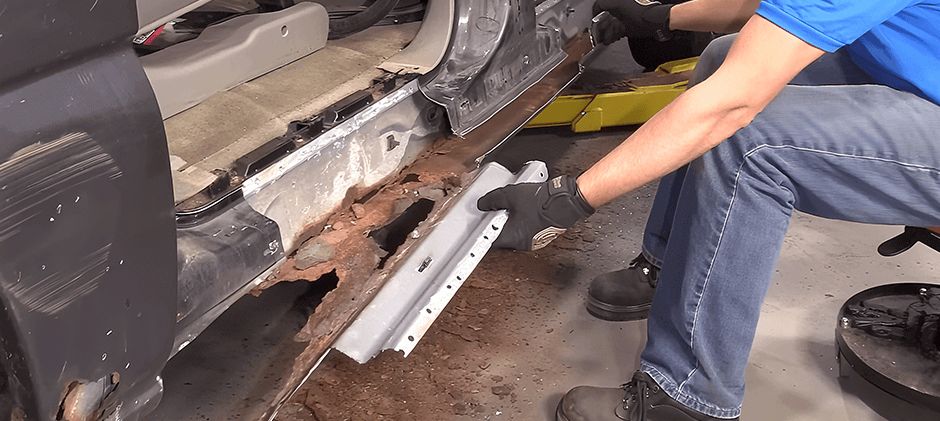

When the rocker panel is too rusty to repair, you’ll need to replace it. You can choose between two common types based on your skills, budget, and desired result: weld-in panels or slip-on panels.

Weld-In Rocker Panels

Weld-in rocker panels are full replacements. It is cut out the old, rusty metal completely, and weld the new panel in its place. This way is the hardest because it restores the car’s strength as it was from the factory. The job involves cutting carefully, fitting the new panel, and welding it on. After welding, the seams are ground smooth. Then primed, filled if needed, and painted. It’s usually best to have a body shop do it.

Slip-On Rocker Panels

Slip-on rocker panels cover old, damaged ones. They’re slightly larger to slide over the original panel, and installers usually secure them with glue, screws, or rivets. This method makes installation easier for most DIYers since it doesn’t require welding. You just clean off the rusty area, treat it with rust converter to stop more rust, then attach the new panel on top. It’s a quicker and cheaper fix, but mostly for looks — it doesn’t bring back the strength that was lost from rust. Also, unless you cover them with body filler, the screw or rivet heads might still be visible.

How Much Does a Rocker Panel Replacement Cost?

You might be wondering about the cost to replace rusted or broken rocker panels. When sourcing the parts from FridayParts, the cost is quite manageable. For example, an individual driver or passenger side panel for a popular model like the E-Z-GO TXT golf cart costs around $30, while a complete diamond plate pair can be purchased for under $45. Labor could cost around $1000 to $4000. This may seem a bit expensive, but this already includes the cost of removing the door and polishing (for welded-type panels) after installation.

Maintaining Your Rocker Panel

Replacing rocker panels can be expensive and take a lot of work, so prevention is the best way. With some simple, regular maintenance, you can make your rocker panels last much longer and keep them from rusting for years.

- Wash Your Vehicle Regularly: Frequently clean the under of the car, including the chassis and wheel arches. Wash your car more often in winter to remove corrosive road salt as quickly as possible.

- Inspect and Clear Drain Holes: Check the small drain hole under the rocker frequently. Use a small piece of wire or compressed air to clear out any mud or debris, ensuring the water drains smoothly.

- Touch Up Paint Chips Immediately: Check the rocker panel frequently for paint peeling or scratches from stones. Clean it up when you find it, then paint it right away, and don’t let it start to rust.

- Consider Protective Coatings: If you want better protection, especially when you are new or have just repaired, you can spray a layer of rubberized undercoating or a wax-based rust-proofing spray on the inside and outside.

Final Thoughts

Due to their special location, rocker panels are highly prone to rust. Knowing its function, why it rusts, and how to take care of it can extend its life. Finding affordable, high-quality rocker panel parts is essential when replacement is needed. FridayParts offers a wide selection of rocker panels for golf carts, helping you fix your equipment faster and for less.