The head gasket is sandwiched between the engine block and the cylinder head to seal the combustion chamber. It enables the engine to establish compression properly without mixing coolant and oil. If something goes wrong with the head gasket, it could lead to engine failure. This part is not cheap to repair. Find out in advance why the head gasket leak and what will happen if it breaks.

Common Symptoms of a Head Gasket Leak

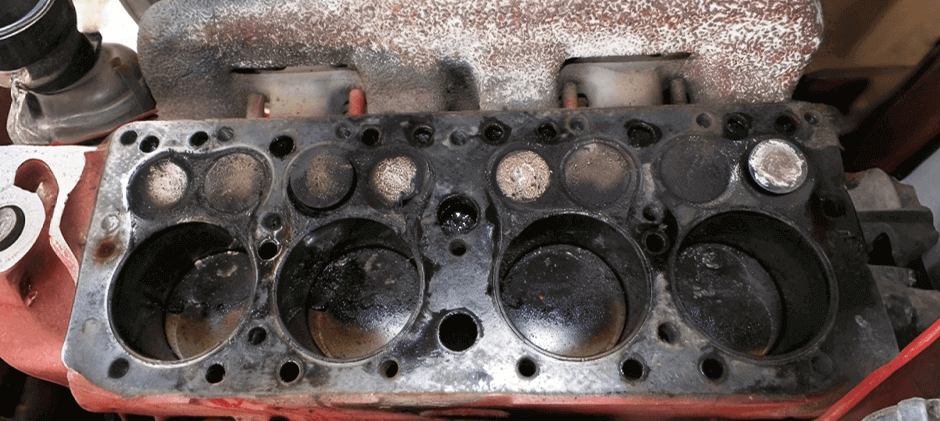

A bad head gasket on a heavy diesel engine shows different symptoms, depending on where the seal breaks. This gasket seals in combustion pressure, plus the coolant and oil passages. A leak anywhere between these parts will trigger clear warning signs. Watch out if your machine starts acting like this:

Engine Overheating

A head gasket leak can force hot combustion gases into the cooling system. This pushes out coolant and creates air bubbles. It can also make coolant leak out of the system—either dripping onto the ground or seeping into a cylinder. Either way, the engine can’t cool itself properly. Your temperature gauge will shoot up into the red zone, especially when the machine is under load.

Big Power Drop

Suddenly, your excavator can’t lift a full bucket, or your bulldozer bogs down when pushing heavy loads. A blown head gasket might leak between two nearby cylinders, or from a cylinder to the outside. That causes a huge loss of compression. Without good compression, your diesel engine can’t make the power it needs to get the job done.

Milky, Frothy Engine Oil

Check your dipstick or take a peek under the oil filler cap. If you see a thick, milky, mayonnaise-like gunk, that’s a serious red flag. It means coolant is leaking past the head gasket and mixing with the engine oil. This milky oil can’t lubricate anymore. It’ll cause fast wear on bearings, camshafts, and other vital internal parts.

Constant Bubbles in the Coolant Reservoir

If you see bubbles popping up nonstop, that’s a dead giveaway. Combustion gases are forcing their way into the coolant lines. This makes the system way more pressurized than it should be, and it’s a textbook sign of a blown head gasket.

White Smoke from the Exhaust

Diesel engines can puff out black or blue smoke every now and then—that’s normal. But thick white smoke that smells sweet? That’s a whole different issue. It’s steam, plain and simple. Coolant is leaking into the combustion chamber and burning up with the fuel. You’ll notice it the most when you start the engine, but it might stick around even after the engine warms up.

Rough Engine Running

An engine with a compression leak from a bad head gasket will often run rough, shake, or have a noticeable “miss” in its rhythm. That’s because one or more cylinders aren’t putting out their full power to turn the crankshaft.

Coolant or Oil Leaking Outside the Engine

Sometimes the leak is visible from the outside. You might see coolant or oil seeping out of the gap where the cylinder head meets the engine block. It’s messy, but usually less damaging right away than an internal leak.

The Trouble with Ignoring Blown Head Gasket Symptoms

If you keep running a machine with a bad head gasket, you’re asking for a whole chain of breakdowns.

- Warped or cracked cylinder head: Constant overheating can warp that big, heavy cast-iron cylinder head. Once it warps, you’ll have to shell out for pricey machine shop work to get it sealing right again. In the worst cases, the head will crack—and then it’s totally useless.

- Scored cylinder liners and damaged pistons: If coolant keeps leaking into a cylinder, it’ll wash away the thin oil film that lubricates the piston rings and cylinder walls. This metal-on-metal rubbing will quickly scratch up the cylinder liner and ruin the piston. Fixing this means tearing the whole engine apart.

- Fried engine bearings: Oil mixed with coolant is a death sentence for your engine bearings. The water and ethylene glycol in the coolant kill the oil’s thickness and protective qualities. That leads to super-fast wear and failure of the main and rod bearings—and usually, that’s the point where the engine is toast.

- Cooling system corrosion: When exhaust gases get into the coolant, they mix with the water to corrosive acids. These acids damage the radiator, water pump, thermostat, and hoses. Even fix the head gasket, a bunch of cooling system failures in the end. Replacing a few gaskets and bolts is cheaper than fixing the engine. And don’t even get me started on the huge costs from project delays.

What Causes Head Gasket Failure?

Gasket failure almost always stems from an underlying problem that puts too much stress on it.

Prolonged Overheating

When an engine overheats, the aluminum cylinder head and the steel head bolts expand at different rates. A rubbing motion can ruin the gasket’s seal. Overheating usually comes down to environmental issues:

- Clogged Radiator Fins: Dirt, dust, mud and debris pile up on the radiator. This blocks airflow and stops the engine from cooling down.

- Broken Water Pump or Thermostat: A faulty water pump won’t circulate coolant. A stuck thermostat keeps coolant from reaching the radiator at all.

- Low Coolant Levels: A leak somewhere else in the system can drain coolant. That makes the engine run hot fast.

Extreme Combustion Pressure

Head gaskets are for handling combustion force, but some conditions push pressure way past their limits. In diesel engines, this usually happens for these reasons:

- Wrong Injection Timing: Injecting fuel too early makes pressure build up too fast in the cylinder.

- Faulty Injectors: A leaking injector or one with a bad spray pattern creates hot spots and pressure spikes.

- Engine Lugging: Running the engine at super low RPM while under heavy load stresses out all internal parts—including the head gasket.

Improper Installation

A head gasket is only as good as the job done to put it in. If the cylinder head and engine block surfaces aren’t perfectly clean and flat, or if head bolts aren’t tightened to the right torque and in the correct order, the gasket will fail early. That’s why following the manufacturer’s service manual exactly is a must.

Age and Operating Hours

After thousands of hours of use, the constant heating and cooling cycles make the gasket material hard and brittle. Eventually, it can just wear out and fail from all that fatigue.

How to Test for a Blown Head Gasket?

Is your head gasket leaking? Just do some simple tests. Don’t go tearing the engine apart right away.

Visual Check

Check the oil dipstick for that milky texture. If it’s got oil in the coolant, it’ll look like a dark, greasy film floating on top. Also, check around the cylinder head for leaks on the outside.

Cooling System Pressure Test

Hook a special tester up to the radiator opening. Pump it up to the pressure listed on the radiator cap (usually 15–20 PSI). If the pressure drops steadily, there’s a leak somewhere. If you can’t find an external leak, it’s probably leaking inside the engine.

Combustion Leak Test

This test uses a special chemical fluid that changes color when it touches combustion gases. Set the tester over the open radiator neck while the engine’s running. If the blue fluid turns yellow or green, that’s proof that exhaust gases are leaking into your cooling system.

Compression Test

A compression test tells you how well each cylinder seals up. On a diesel engine, pull out each fuel injector and screw a compression gauge into the hole. Then crank the engine and jot down the pressure reading for every cylinder. A healthy engine will have pretty much the same reading across all cylinders. A much lower reading in one cylinder means something’s wrong, and low readings in two side-by-side cylinders are almost a sure sign the head gasket between them is blown.

Preventive Maintenance Tips

The best repair is not to have to. Do preventive maintenance to extend the service life of the head gasket.

- Keep your radiator clean: After finishing work every day, use compressed air or a pressure washer (stay away from the heat sink and don’t bend the heat sink) to blow all dust, scale and debris off the heat sink and oil cooler heat sink.

- Monitor your gauges: Make it a habit for all operators to keep an eye on the temperature gauge at all times. If the temperature exceeds the normal working range, stop the machine immediately for inspection.

- Maintain coolant quality and level: Check the coolant regularly to see if it is enough, and add it in time if it is not enough. Flush and change the coolant according to the manufacturer’s recommended cycle.

- Proper operation: Make sure the operators are using the equipment according to the rules. Never overload the engine. After a heavy-load operation, let the engine cool down sufficiently before shutting down.

- Select high-quality parts: Whether it’s replacing a small thermostat or doing a major repair, as long as you’re working on the engine, you must use high-quality accessories. Cheap, low-quality cylinder liners simply cannot withstand the high-intensity work of heavy-duty diesel engines.

Summary

Identifying the symptoms of a damaged head gasket early can prevent more extensive and costly engine repairs. Are you already seeing signs of a damaged head gasket? FridayParts provides the parts and tools you need to complete the repair easily.