If you’ve ever torn down an engine or rebuilt machinery, you’ve heard of Main Bearing vs. Rod Bearing. They may look like simple half‑circle metal shells — but they’re actually the backbone of your engine’s lower end.

In this guide, we’ll clearly explain:

- What each bearing does

- Where they are located

- How to identify wear or damage

- Common repair and prevention tips

By the end, you’ll know exactly what’s what — and how to diagnose bearing issues confidently.

What Engine Bearings Really Do

Bearings in your engine aren’t ball bearings — they’re plain (shell) bearings.

Their purpose: let moving parts spin smoothly with minimal friction.

Here’s how they work:

- Oil under pressure forms a thin film between the bearing and the moving part (the crankshaft).

- The metal surfaces never actually touch — they “float” on oil.

- This oil film prevents wear and keeps the crankshaft turning freely even under massive load.

Think of it like controlled hydroplaning — but instead of losing traction, the engine relies on this effect to stay alive.

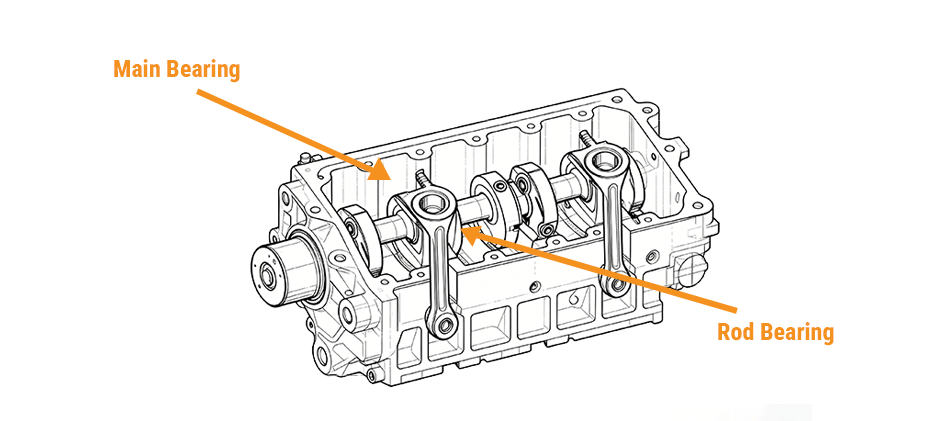

Main Bearings: The Crankshaft’s Foundation

Where They Are: Main bearings are installed in the engine block.

Each crankshaft journal sits on a pair of bearing shells — one in the block, one in the cap.

When the cap is bolted down, it sandwiches the crankshaft in position.

What They Do

- Support the entire crankshaft inside the block.

- Keep it centered and stable as it spins.

- Carry the full load from all pistons and connecting rods.

A typical 4‑ or 6‑cylinder engine will have 4–5 main bearings spaced along the crankshaft.

Thrust Bearing: The Axial Guardian

One of the main bearings has an extra job — it’s the thrust bearing.

This special bearing prevents the crankshaft from moving forward or backward (axial movement).

Its Role

When your clutch engages (on manual equipment) or when a hydraulic pump adds resistance, it pushes the crankshaft lengthwise.

The thrust bearing’s side flanges absorb this force, keeping the crankshaft from sliding in the block.

Tip: The thrust bearing is part of the main bearing set, not a separate component.

Rod Bearings: The Force Connectors

Where They Are

Rod bearings sit at the big end of each connecting rod, wrapped around the crankshaft’s rod journals (also called crankpins).

Each connecting rod uses two half‑shells:

- One in the rod body

- One in the rod cap

What They Do

When combustion pushes the piston down, the connecting rod transfers that exploding energy to the crankshaft through the rod bearing.

In Summary

- Every piston has its own pair of rod bearings.

- Their job is to let the connecting rod rotate freely around the crankshaft journal while supporting extreme forces.

Main Bearing vs. Rod Bearing: Quick Comparison Table

| Feature | Main Bearings | Rod Bearings |

|---|---|---|

| Primary Job | Support the crankshaft inside the engine block. | Connect each connecting rod to the crankshaft. |

| Location | In the block’s main saddles and bearing caps. | In the “big end” of each connecting rod. |

| Contacts (Journal Type) | Ride on the main journals of the crankshaft. | Ride on the rod journals (crankpins). |

| Load Type | Support the static and rotating weight of the crankshaft. | Handle up‑and‑down force from the piston’s power stroke. |

| Size | Larger diameter. | Smaller diameter. |

| Special Version | One includes thrust faces for axial control. | None — purely rotational load. |

| Failure Sound | Deep, heavy rumble or growl. | Sharp metallic “rod knock” that follows RPM. |

Main Bearing vs. Rod Bearing: Common Bearing Problems

When lubrication fails or bearings wear, you’ll notice distinct symptoms:

Rod Bearing Failure

- Noise: Sharp knocking that rises and falls with RPM.

- Worst under: Load, but still audible when free‑revving.

- Cause: Oil film loss between the connecting rod and crank journal.

Main Bearing Failure

- Noise: Deep, heavy rumble or thump.

- Worst under: Acceleration or heavy load.

- Feel: You can sometimes feel it as a vibration in the block.

In both cases:

- Oil pressure will drop.

- Drained oil will show metallic flakes or glitter.

- Continuing to operate may seize the engine.

What to Do if You Suspect Bearing Damage

Step 1 – Stop Running the Engine or Machine

Running it further can destroy the crankshaft.

Step 2 – Check Oil Condition and Pressure

If the oil looks shiny or contains metal, you likely have bearing wear.

Step 3 – Disassemble and Inspect

For accurate confirmation:

- Use a feeler gauge or Plastigage to measure bearing clearance.

- Look for scoring, pitting, or uneven wear on bearing shells and crank journals.

Step 4 – Replace and Rebuild as Needed

- Slight wear → Replace bearings and polish crank.

- serious damage → Crankshaft grinding or full rebuild needed.

Always replace bearings in matching sets (main or rod) — never mix types or brands.

Maintenance & Prevention: How to Extend Bearing Life

| Tip | Why It Matters |

|---|---|

| Keep oil changes on schedule | Dirty or thin oil is the #1 cause of bearing wear. |

| Warm up before full load | Cold, thick oil doesn’t flow properly to bearings. |

| Check oil clearance during rebuilds | Too tight = oil starvation. Too loose = pressure loss. |

| Keep oil passages clean | Sludge blocks the lubrication, starving the bearings. |

| Use the correct torque when installing | Uneven torque or dirt under caps can distort clearances. |

Quick Recap

- Main bearings = Support the crankshaft in the engine block.

- Rod bearings = Connect each connecting rod to the crankshaft.

- Thrust bearing = A main bearing that prevents axial movement.

- Both types rely entirely on clean, pressurised oil for survival.

- Bearing failure = low oil pressure + metallic noise + expensive downtime.

Why It Matters for Off‑Road Machinery

For excavators, loaders, or generators, bearing wear doesn’t just mean repair bills — it means lost uptime.

Keeping your crankshaft bearings healthy ensures:

- Smooth, stable power delivery

- Reliable oil pressure under load

- Protection from catastrophic engine failure

If you’re rebuilding, always source OEM‑grade bearing kits that match your engine model and tolerance class.

Your Trusted Parts Partner

At FridayParts, we supply precision main and con rod bearings for diesel and gasoline engines — built for off‑road reliability and long service life.

Whether you’re overhauling a small generator or a heavy-duty excavator engine, you’ll find:

- Complete bearing sets (main, rod, thrust)

- Compatible gaskets and seals

- OEM‑match fitment and fast delivery

Explore your engine’s bearing kits here → FridayParts.com

Simple Summary:

- Main Bearing = engine foundation

- Rod Bearing = power connector

- Thrust Bearing = motion limiter

Keep them lubricated, installed correctly, and inspected on schedule — and your engine will reward you with years of smooth, uninterrupted work.