When dealing with off-road machinery, stripped bolts can significantly slow down the maintenance process, delay the operation schedule, and even lead to costly downtime. No matter whether you are repairing the hydraulic cylinder, disassembling the wheel hub, or working on the excavator undercarriage, it is of great importance to master the proper way of safely removing the damaged bolt. In this guide, we shall introduce several time-tested methods and practical advice by which you may efficiently remove the stripped bolts and prevent such matters from occurring again.

Key Takeaways

- Stripped bolts often happen due to over-tightening, corrosion, or using the wrong socket size.

- There are multiple ways to remove them — using drills, impact wrenches, Torque Wrenches, and other specialized hand tools.

- Selecting high-quality replacement bolts, sockets, and impact wrench parts can minimize future failures.

- Regular inspection and proper storage of tools extend both the tool and machine lifespan.

Why Does Stripping Happen?

Most stripped bolt-on heavy equipment occurs during routine maintenance tasks — tightening track shoes, mounting hydraulic lines, or assembling blade frames. Let’s look at some common causes:

- Overtightening: Using an impact tool without a torque limiter can easily deform bolt heads.

- Wrong tool choice: Using a 12-point socket when a 6-point is needed may cause rounding on bolt edges.

- Corrosion and rust: Moisture, mud, and vibration from off-road environments accelerate wear on bolt threads.

- Poor alignment: Starting a bolt at an odd angle cross-threads it, making it lock into place incorrectly.

Before removing tight fasteners, always clean the bolt area with a wire brush and apply penetrating oil. This simple step avoids heat build-up and reduces friction.

How to Remove a Stripped Bolt?

When a bolt becomes rounded or jammed, different removal methods apply depending on how badly it’s damaged. Here are four of the most efficient techniques that work on off-road and construction machinery.

1. Using a Wrench

A high-quality wrench remains one of the most reliable tools in the shop. For a slightly stripped bolt, choose a six-point socket wrench over a twelve-point version — it grips more surface area and reduces slipping.

Steps:

- Tap a slightly smaller socket onto the bolt head using a hammer.

- Attach your breaker bar for additional leverage.

- Turn the wrench slowly and steadily — sudden movements increase the chance of rounding the bolt further.

Pro Tip: Apply valve grinding compound inside the socket for extra grip when the bolt head is heavily worn.

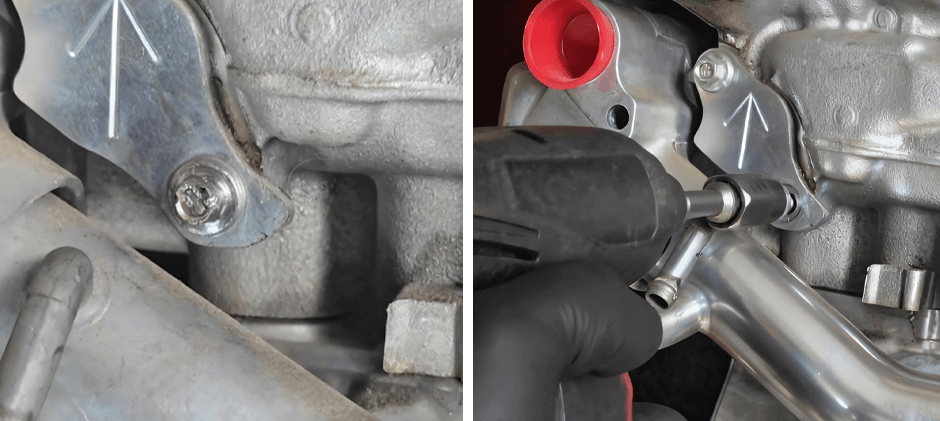

2. Using an Impact Wrench

For stubborn fasteners, a powered solution is often necessary. An impact wrench delivers rotational force through rapid bursts, making it ideal for loosening bolts secured by rust or extreme tension.

How it’s done:

- Firmly seat the socket onto the bolt head.

- Use moderate torque settings to avoid stripping it further.

- Gradually increase the torque only if the bolt doesn’t budge.

Pro Tip: A loose fit or overly rounded bolt head can worsen quickly under heavy torque. Inspect both the socket and the fastener before pulling the trigger.

Maintaining your impact wrench parts, such as anvils and hammers, is crucial. Worn components deliver inconsistent torque and can damage sensitive bolt heads over time. Explore replacement impact wrench parts to ensure accuracy and long-term reliability.

3. Using a Drill and Extractor Set

When other tools fail, drilling into the bolt often becomes the last resort. Drilling must be done carefully to prevent enlarging or cracking the surrounding metal threads.

Start by marking the exact center of the bolt head. Then, use progressively larger drill bits until you reach the right depth for an extractor.

| Step | Tool | Description |

|---|---|---|

| 1 | Center punch | Keep the drill aligned with the bolt center |

| 2 | Small drill bit | Create a starter hole |

| 3 | Extractor | Twist counterclockwise to pull out the bolt |

| 4 | Lubricant | Use engine oil or WD‑40 for smoother drilling |

For precision, frequently inspect your drill parts — particularly gear assemblies, chucks, and carbon brushes — to maintain optimal torque and rotation. Drilling with dull bits or worn components generates heat and may seize the bolt completely.

Pro Tip: Dip your drill bit occasionally in oil during operation. Lubrication cools the metal and extends tool life.

4. Using a Torque Wrench for Reassembly

Once the stripped bolt is removed, you’ll need to tighten the new one properly. A Torque Wrench ensures precision tightening according to manufacturer specifications.

Using a torque wrench ensures you apply just the right force without damaging threads or compressing seals. Digital models facilitate this process by displaying exact values and providing audible alerts when the correct torque is achieved.

Combine your torque tools with durable hand tools from FridayParts for efficient field maintenance of excavators, loaders, and tractors.

How to Prevent Future Stripped Bolts?

Prevention starts with disciplined maintenance habits. Some measures can drastically reduce the risk of stripping:

- Use the correct tool size. Match the socket to the bolt head precisely.

- Apply even torque. Always use a Torque Wrench during final tightening.

- Clean bolt threads. Dirt buildup increases resistance and friction.

- Avoid overuse of impact tools. Use them for loosening, not final tightening.

- Replace damaged fasteners. Once worn or corroded, bolts should never be reused.

Keep all hand tools in clean condition and store them properly. Check tool surfaces for chips or wear before starting any job to guarantee consistent performance in harsh environments.

Quick Tips for Removing a Bolt

If the bolt head is slightly rounded, try using locking pliers for initial movement.

Heat can sometimes help — carefully apply a torch to expand the metal slightly before turning.

Tap a smaller metric or imperial socket size onto the head with a hammer for a tight grip.

If corrosion is severe, use rust dissolver sprays and wait a few minutes before attempting extraction.

Pro Tip: Always inspect the mating threads after removing the bolt. Use a thread chaser to clean the hole before inserting a new bolt, and apply anti-seize compound to prevent future seizing.

Recommended Hand Tools and Maintenance Products

Heavy equipment repair depends on reliable shop-grade tools. In addition to drill parts and impact wrench parts, investing in comprehensive tool sets ensures fewer interruptions on worksites. Check FridayParts’ full range of durable hand tools designed for off-road machinery — including adjustable spanners, filter wrenches, and diagnostic kits.

| Tool Type | Ideal Use | Maintenance Tip |

|---|---|---|

| Combination Wrench | General fastener tightening | Keep your jaws clean to prevent slipping |

| Spanner Wrench | Hydraulic fittings | Store dry to avoid corrosion |

| Digital Torque Wrench | Calibrated bolt tightening | Verify calibration yearly |

| Drill Driver Set | Bolt extraction, pilot holes | Replace bits regularly |

Off-road machines endure mud, vibration, and heat — all enemies of healthy fasteners. Periodically re‑torquing bolts ensures assemblies remain tight under harsh loading. Preventive care is cheaper than emergency downtime caused by failed bolts. Replace old fasteners with high‑grade OEM or aftermarket bolts, and verify proper torque after initial hours of operation.

Summary

A stripped bolt might look minor, but it can bring major projects to a halt. Using the right combination of Torque Wrench, wrench, and precision hand tools helps you restore function quickly and safely. When a part or tool needs replacement, FridayParts offers a broad selection of affordable, high-quality options—from drill parts to impact wrench parts—suitable for most heavy equipment brands. Order your professional‑grade tools today at FridayParts.com and keep your off‑road machinery ready for the toughest terrains.