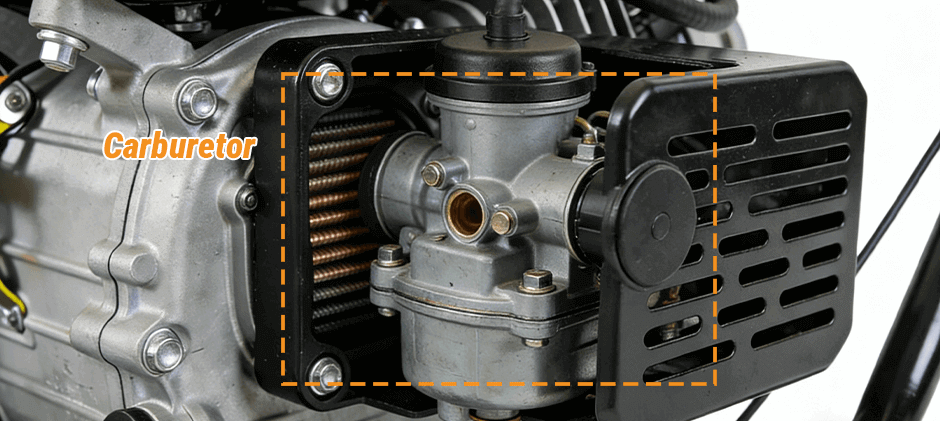

A clogged carburetor is the main reason a snow blower won’t start after storage. Old fuel dries into sticky varnish and blocks tiny fuel holes. This guide shows how to clean snow blower carburetor parts safely and quickly, using simple tools. The same method works for many small engines on off-road equipment that sits for weeks or months.

Why Does A Snow Blower Carburetor Get Clogged?

Old gas is the real problem. Gasoline can go stale in 30–60 days, and ethanol fuel pulls in moisture that leaves gum and corrosion in the carburetor.

Storage makes it worse. Off-road machinery often sits in cold sheds or trailers, and that temperature swing speeds up fuel breakdown.

Clear Statement: If the machine ran fine last season but won’t run now, the carburetor is the first place to look.

3 Symptoms of a Dirty Carburetor

Surging is a common warning sign. The engine speeds up and slows down because it’s not getting steady fuel.

Only running on choke is another clue. The choke reduces air, which “helps” when the main jet is partly blocked.

No-start can still be fuel-related. If you have spark and the engine turns over, a clogged jet may be stopping fuel completely.

“Air + Fuel + Spark = Run.”

If one is missing, the engine won’t start. Before assuming it’s the carburetor, it’s wise to confirm you have a good spark. You may need to know how to test a spark plug with a multimeter and have the correct size socket for a spark plug on hand. If it’s not a fuel or spark issue, you might have common bad starter symptoms.

What Tools Do You Need Before You Start?

Basic hand tools are enough. You usually only need a socket set, screwdrivers, and pliers.

Carb cleaner matters. Use real carburetor cleaner spray (not just brake cleaner) to dissolve varnish.

Eye protection is not optional. Carb spray can bounce back fast.

Simple checklist:

- Socket set (often 8mm/10mm or 1/2″)

- Phillips + flat screwdriver

- Pliers or fuel-line clamp

- Carb cleaner spray

- Thin wire (twist-tie wire or jet cleaning wire)

- Rags + small container for fuel

When Should You Stop And Think About Safety?

Fuel fumes ignite easily. Work outside or in a well-ventilated area, away from heaters, welders, and cigarettes.

Hot parts burn skin fast. Let the engine cool before you touch the muffler area.

Spinning parts can hurt you. Remove the ignition key and disconnect the spark plug wire before you start.

Clear Statement: If you can smell strong gas, you need more airflow and less risk.

8 Steps to Clean Your Snow Blower Carburetor

Step 1: How Do You Confirm Fuel Can Flow?

Fuel flow must be possible. Make sure the fuel shutoff valve (if you have one) is in the ON position and the fuel line is not cracked or pinched.

Step 2: How Do You Reach The Carburetor Fast?

Access is the first job. Remove the plastic cover, heater box, or air intake housing until you can see the carburetor body and bowl.

Step 3: How Do You Prevent Fuel Spills?

Fuel spills make a mess and add danger. Clamp the fuel line, then slide the hose clamp back and pull the line off the carb.

Step 4: How Do You Avoid Linkage Mistakes?

Linkages must go back in the same holes. Take one clear photo of the throttle/governor linkage before you unhook anything.

“One photo now saves one hour later.”

Step 5: How Do You Remove The Carb Bowl?

The bowl holds the worst gunk. Remove the bowl nut/bolt at the bottom, lower the bowl carefully, and pour old fuel into a container.

Step 6: How Do You Clean The Main Jet The Right Way?

The main jet is usually the blockage point. For some models, you might be able to clean a carburetor without removing it entirely. Otherwise, spray carb cleaner through the jet and confirm it shoots through in a strong, straight stream.

Use a thin wire only to clear the hole. Push gently so you clean debris without damaging the jet.

Step 7: How Do You Clean The Emulsion Tube And Passages?

Tiny side holes also clog. If your carb has an emulsion tube, remove it (if your model allows) and spray through every small hole until it flows clean.

Clean the carb body ports too. Spray into visible passages, the throat, and the idle circuit openings.

Step 8: How Do You Reassemble And Test?

Reassembly must be leak-free. Seat the bowl gasket correctly, tighten the bowl nut snug (not over-tight), reconnect linkages, and reconnect the fuel line.

Start and warm up normally. Let it run for a minute, then open the choke fully and check for a smooth idle.

Clear Statement: A good cleaning means it runs without choke after warm-up and does not surge.

5 Mistakes You Should Avoid

Over-priming can flood the engine. Too much fuel wets the spark plug and makes starting harder.

Forgetting the gasket causes leaks. A pinched bowl gasket can drip fuel onto hot engine parts.

Using drill bits ruins jets. Drilling makes the hole bigger and can permanently mess up the fuel mixture.

Skipping fresh fuel wastes your work. Dirty fuel will clog the carb again fast.

Mixing up linkages changes RPM. Wrong linkage placement can cause unsafe high speed or poor power.

When Should You Replace Instead of Clean?

Corrosion means cleaning may not last. White crusty buildup inside aluminum carb parts often comes back and re-clogs jets.

Damaged parts mean replacement is smarter. A stuck float, worn needle valve seat, or stripped bowl nut can keep causing trouble.

Clear Statement: If it still surges after a careful cleaning, the internal passages may be blocked beyond an easy fix.

How to Prevent Future Clogs

Fresh fuel is the easiest prevention. Use stabilized fuel if the machine might sit for more than a month.

Running it dry helps a lot. At season’s end, shut off the fuel valve (if equipped) and let the engine run until it stops.

Draining the bowl is even better. Many carbs have a bowl drain screw—use it to empty fuel before storage.

“Dry carburetors don’t varnish.”

Final Words

A clean carburetor brings back easy starts, smooth power, and steady RPM for real-world work on gravel lots, access roads, and job sites. If cleaning doesn’t solve it or you need reliable replacements for tune-up and repair, you can find compatible snow blower parts at FridayParts to help keep your off-road equipment ready for the next storm.