A clogged DPF (Diesel Particulate Filter) can slow your machine down or even stop it from working. This guide explains simple, practical ways to clean a DPF so your equipment can run normally again. We’ll cover regeneration (auto cleaning) and what to do when you need to remove the DPF and clean it off the machine.

Why Should You Clean Your DPF Filter?

The DPF traps soot (black dirt from exhaust). That is its job. But when it fills up, the exhaust can’t flow well.

A clean DPF helps you:

- keep normal engine power,

- avoid “limp mode,”

- reduce fuel waste,

- protect parts like the turbo and sensors.

3 Signs of a Clogged DPF Filter

Watch for these common signs:

- DPF Warning Light: The DPF light turns on to tell you the filter is getting full and needs a cleaning cycle (regeneration).

- Loss of Engine Power: The machine may feel weak or slow. A clogged DPF creates backpressure, like a plugged pipe.

- Increased Fuel Consumption: You may burn more fuel doing the same work because the engine has to push exhaust through a blocked filter.

What Happens If You Ignore a Clogged DPF?

If you keep working with a clogged DPF, problems usually get worse:

- The machine may go into limp mode (low power to protect itself),

- The exhaust backpressure can stress the turbocharger,

- High heat and pressure can damage the DPF and other exhaust parts,

- You may end up needing a full DPF replacement, which costs more and takes more time. Some owners consider removing it entirely, but you should know is a DPF delete worth it? before making that choice.

“Think of a clogged DPF not as a suggestion, but as a final warning before major engine trouble.”

How Can You Clean a DPF Filter?

There are a few ways to clean a DPF. Start with the easiest method first.

Method 1: Passive Regeneration (Cleaning While Driving)

Passive regeneration happens by itself when the machine works hard and gets hot enough.

- When the exhaust temperature stays high, soot burns off.

- It usually happens during heavy work at higher RPM (for example: hauling, grading, digging under load).

A common target is keeping exhaust hot for long enough—often around 572°F (300°C) or more (check your manual if your machine lists a specific temperature).

Method 2: Active Regeneration

Active regeneration is controlled by the ECM.

- If passive regen is not enough, the ECM adds extra fuel to raise the exhaust temperature.

- The DPF heats up very high (often around 1100°F (600°C)) to burn soot.

You may notice:

- higher idle,

- different engine sound,

- hot exhaust warning.

Method 3: Forced Stationary Regeneration

If the DPF light starts flashing or the machine asks for regen, you may need a forced (parked) regeneration.

Basic steps (follow your machine manual):

- Park on level ground, away from dry grass, fuel, and other flammables.

- Set the parking brake.

- Start the forced regen using the regen switch/button (if equipped).

- Let it finish (often 20–40 minutes).

This is the main way to clean the DPF without removing it.

How to Clean a DPF Filter Yourself

If regeneration does not work anymore, the DPF may be too full of ash and needs off-machine cleaning.

Step 1: Safety and Removal

- Shut the machine off and let the exhaust cool completely.

- Wear PPE: gloves, safety glasses, and a P100 or HEPA respirator (standard dust masks are insufficient for toxic ash).

- Unplug sensors carefully and remove the DPF canister from the exhaust.

DPF dust is not something you want to breathe in.

Step 2: Cleaning with Compressed Air

This is a common DIY method.

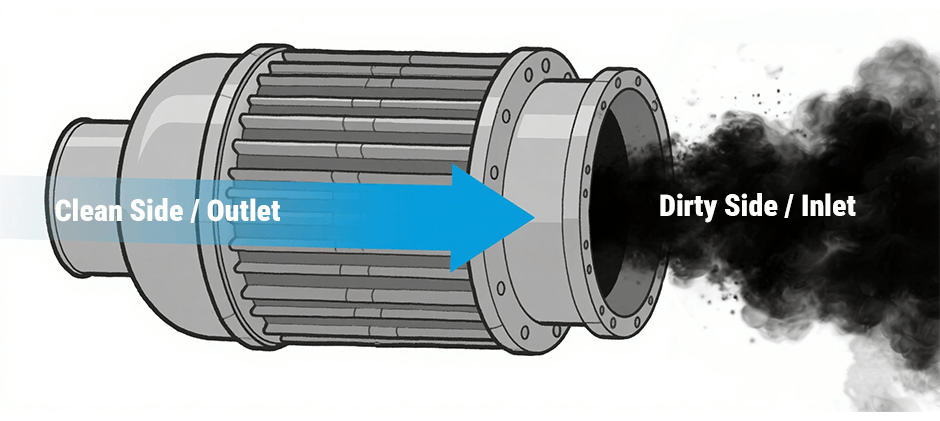

- Blow regulated compressed air from the outlet (clean side) toward the inlet (dirty side).

- This pushes loose soot/ash out the way it came in.

Important:

- Do this outdoors or in a specialized containment area. Blowing air creates a hazardous cloud of heavy metals and ash.

- Do not use too much air pressure. Too much force can crack the ceramic core. Follow the manufacturer’s limit if available.

Step 3: What to Avoid

Avoid these mistakes:

- No pressure washer / no water: water can mix with ash and turn into a hard paste that is very difficult to remove.

- No random chemicals: strong chemicals can damage the coating inside the DPF unless the cleaner is made for DPF use.

Step 4: Inspection and Reinstallation

After cleaning:

- Shine a bright light through the DPF.

- Look for cracks, melted spots, or broken areas.

If the core is damaged, the DPF should be replaced.

If it looks OK:

- Reinstall the DPF (use new gaskets to prevent leaks),

- reconnect sensors,

- REQUIRED: Use a diagnostic scan tool to perform a “DPF Reset” or “Ash Load Reset” so the ECM knows the filter is clean.

- Run a forced regen (if your manual recommends it) to confirm everything works.

When Should You Replace the DPF Filter?

Cleaning cannot fix every DPF. Over time, ash (non-burnable material) builds up and stays there.

Replace the DPF if:

- You see cracks or melting,

- It clogs again very quickly after cleaning,

- The machine displays fault codes indicating a permanent DPF failure.

A good DPF keeps your machine running strong. If yours is worn out, FridayParts replacement is a safer option than repeated regens that don’t work.