The fuel filter is a key part of the fuel system. It keeps dirt and debris out of the engine. How often should you change the fuel filter? Knowing the right replacement frequency makes your equipment last longer. It’s helpful for the engine’s health to keep the fuel system running smoothly.

Recommended Fuel Filter Change Intervals

For heavy equipment like excavators, operating hours are the main thing to go by. As a general rule, replace the fuel filter every 250–500 working hours. The amount varies slightly by brand and model, so use this number as a general reference. The safest bet is to check your operator’s manual and follow the manufacturer’s advice. That said, you’ll need to change it more often in these cases:

- Fuel quality: If you use fuel from on-site tanks (not a regular gas station), it’s way easier for water, dirt and junk to get in. The filter will clog faster, so shorten the replacement time.

- Working conditions: Excavators work in super dirty, dusty places. Dust in the air can get into the fuel tank easily, making the filter work harder. Changing it early in these tough conditions is a cheap way to avoid trouble.

- Machine age: Older machines usually have gunk built up in the fuel tank, which clogs new filters really quickly.

At the end of the day, changing the fuel filter on time (or even a little early) is the easiest, most cost-effective way to keep the fuel system from breaking down. Less downtime, more work, and your machine will last a lot longer.

Signs Your Fuel Filter Needs Replacing

When the fuel filter starts to clog, as in the case of an excavator, there are usually some obvious signs. If left unchecked, the problem can easily drag on. The following situations are all signals that need to be paid attention to:

- The engine is weak: When digging, lifting heavy stuff or climbing hills, the machine is slow to react and lacks power. This is usually from a clogged fuel filter— the engine isn’t getting enough fuel to work at full strength.

- Starting is difficult: The engine takes longer to start, or you have to try a few times to get it going. This is almost always a clogged fuel filter. Bad fuel flow makes ignition harder, especially when it’s cold.

- Unsteady and jittery operation: A steady supply of fuel is required for the engine to function properly. After the filter is blocked, the oil supply is more and less frequent, and the engine is prone to vibration and unstable operation. This is more obvious when the engine is loaded, and sometimes abnormal sounds can be heard.

- More black exhaust smoke: A little smoke from a diesel engine is normal, but if it suddenly belches a lot of black smoke, the fuel isn’t burning right. That’s often from a dirty fuel filter messing up the fuel supply.

- Higher fuel use: If you’re going through fuel a lot faster than usual, the engine’s not working as efficiently. Fuel struggles to get through a clogged filter, so the engine burns more to keep running.

If these conditions occur, checking and replacing the fuel filter as early as possible can often avoid greater failure and downtime losses.

Why Replace Your Fuel Filter?

It’s easy to assume the diesel you put in your machine is clean, but that’s almost never true. Contaminants get in at every stage—from the refinery and delivery truck, right down to your machine’s fuel tank and the on-site storage tank. Here’s what’s usually in the fuel:

- Dirt and dust: Always floating around on construction sites

- Rust: Flakes off the inside of old fuel tanks and barrels

- Water: Condensation builds up in diesel tanks all the time, and it leads to algae growth that creates a thick, sludgy gunk.

Without a fuel filter, these particles would wreck your fuel system in no time. Modern heavy equipment—especially machines with Tier 4 engines—uses high-pressure common rail (HPCR) fuel systems. These systems run at super high pressure and have ultra-tight precision parts that can’t handle contamination. A clogged fuel filter that’s left in place stops working eventually. Contaminants will bypass it and cause costly, serious damage to key parts:

- Fuel injectors: Even tiny specks of debris can clog or ruin an injector.

- Fuel pump: The pump has to work way harder to push fuel through a clogged filter, which makes it wear out fast.

- Engine internal parts: In the worst case, unfiltered fuel can scratch cylinder walls and damage pistons.

Changing a fuel filter is a simple, cheap maintenance job. Ignore it, and you’ll end up with some of the most expensive repairs your machine can have.

Step-by-Step Guide to Change Your Fuel Filter

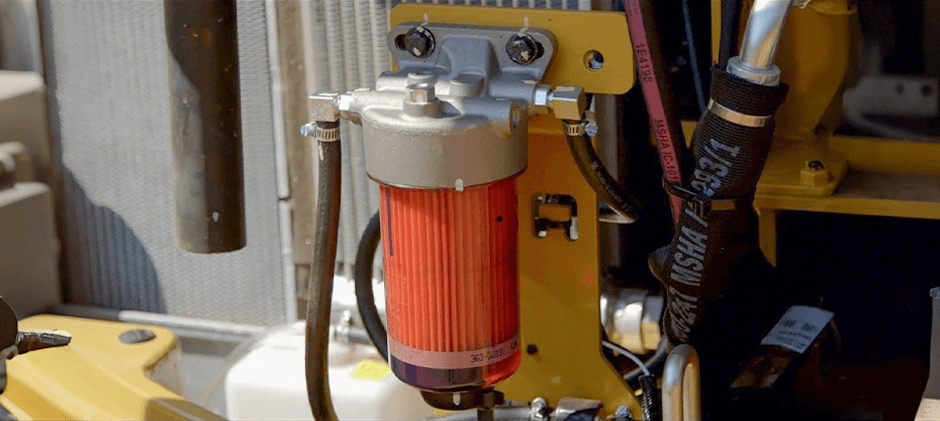

You can change an excavator’s fuel filter yourself—it’s a total breeze. Just remember, most excavators have two filters: a primary filter/water separator and a secondary fine filter. The best move is to replace both of them at the same time. Prepare tools: a filter wrench, a drain pan, clean rags, and your new filters. Safety always comes first, too.

Park and Secure the Machine

Park the excavator on flat ground, lower the boom, arm and bucket all the way down to the ground. Turn off the engine and lock all the safety latches.

Clean the Filter Area

Dirt’s almost always caked around the fuel filters. Wipe down the filter housing and the area around it with a rag, or blast it with compressed air to get it spotless. This keeps dirt from falling into the clean part of the fuel system when you take the old filter off.

Let the Pressure Out of the Fuel System

Check your service manual for exactly how to do this—it’s super important for safety, so fuel doesn’t spray out under pressure.

Drain and Remove the Old Filter

Set the drain pan under the filter. If it’s the primary filter with a water separator bowl, open the drain cock to let out any water and fuel. Then use the filter wrench to twist the filter counter-clockwise and pull it off. Expect a little fuel to spill; it’s normal.

Prep the New Filter

Slather a thin layer of clean diesel or engine oil on the rubber gasket on top of the new filter. This makes for a tight seal and stops the gasket from tearing. Most important part: fill the new filter all the way up with clean diesel first. This gets air out of the system and makes priming way easier.

Put the New Filter On

Screw the pre-filled new filter onto the housing by hand first. Twist it until the gasket touches the base, then tighten it another ½ to ¾ turn—don’t crank it too tight. Over-tightening can strip the threads or damage the gasket. If the water separator bowl is reusable, clean it and pop it back on the new primary filter.

Prime the Fuel System

Changing the filter lets air into the fuel lines, and you need to get it out. Locate the manual primer pump on the filter housing—it’s usually a small button or plunger. Pump it repeatedly until it feels firm, which means the filter’s full of fuel and pressure’s built up. You may need to open a bleed screw while priming, so check your manual for that step.

Start the Engine and Check for Leaks

Start the engine up. It might run a bit rough for a few seconds as the last of the air clears out. Once it’s running smoothly, check the new filter and all connections closely for fuel leaks. If you see any fuel dripping, shut the engine off right away and tighten the filter or fittings as needed.

How Long Can You Run With a Clogged Fuel Filter?

Never run the machine if the fuel filter’s clogged. It might still sputter along, but it’s a huge risk.

A clogged filter makes the fuel pump work way harder, and dirt and gunk can easily get past the filter—right into the injectors and the engine itself. Those tiny particles will wear out the engine bad, and fixing that will cost a fortune. Worse yet, if the machine dies suddenly on the job, your project schedule will get thrown off. The loss from that is way bigger than the cost of a new fuel filter.

Tips to Maintain Your Fuel System

Staying on top of maintenance is the best way to keep your excavator’s fuel system running strong for as long as you own it.

- Use good diesel fuel: Buy your diesel from a trusted supplier that’s known for clean, quality fuel—always if you can.

- Take care of your fuel storage tanks: If you keep fuel on the job site, check the tanks often for water and gunk at the bottom. Keep them sealed tight and protected from the weather.

- Drain the water separator every day: Make this part of your pre-start check each morning. Most primary filters have a clear bowl on the bottom; open the small drain valve until clean fuel comes out, to get rid of any water that’s built up.

- Replace filters on schedule: Don’t try to make your filters last longer than they should. Replace them when the manufacturer says to, even sooner if you’re working in tough, dirty conditions.

- Use good quality filters: Don’t skimp on fuel filters. Pick high-quality aftermarket ones that meet or beat the OEM specs. This makes sure the filtration works right and the filters last.

Conclusion

If you’re mechanically familiar, you might be able to replace the fuel filter yourself. Choosing the right filters and having the right maintenance knowledge is a simple task. FridayParts offers a wide variety of fuel filters that are widely compatible with major heavy equipment brands at affordable prices.