A heavy equipment’s fuel supply system has several key parts working together to make sure the engine gets a steady, reliable fuel flow no matter the working conditions. One super important part is the fuel rail pressure sensor—it checks the pressure in the fuel rail, and helps the engine’s control system adjust how much fuel is injected exactly. But what happens if this sensor goes bad? What are faulty fuel rail pressure sensor symptoms? And can you still run the machine if the sensor’s having issues?

What Is a Fuel Rail Pressure Sensor?

The fuel rail pressure sensor is a key part that monitors fuel pressure. In today’s common rail diesel engines, fuel is pressurized to an extremely high level, stored in a pipe called the fuel rail, and then distributed to each fuel injector. On heavy equipment, this pressure can often hit thousands or even tens of thousands of PSI.

The fuel rail pressure sensor measures the actual pressure in the fuel rail in real time and sends the data to the engine control module (ECM). The ECM adjusts how the high-pressure fuel pump and fuel injectors work according to this info. Making sure the engine gets the right amount of fuel, no matter the working conditions.

Simply, this sensor lets the engine know: What the current fuel pressure is, and if it needs more fuel, or a little less. If the fuel rail pressure sensor fails, the ECM can’t control fuel injection correctly. The engine might lose power, use more fuel, or even struggle to start.

Bad Fuel Rail Pressure Sensor Symptoms

A bad sensor’ll give you clear warning signs. Here are the most common red flags of a faulty fuel rail pressure sensor to watch for.

Check Engine Light & Fault Codes

The ECM’s always checking all its sensors. If the fuel rail pressure sensor’s signal is off, it’ll instantly turn on the Check Engine Light (or MIL) on your dashboard. Hook up a diagnostic scanner, and you can see specific fault codes for the fuel rail pressure circuit, like:

- P0190: Fuel Rail Pressure Sensor Circuit Malfunction

- P0191: Fuel Rail Pressure Sensor Circuit Range/Performance

- P0192: Fuel Rail Pressure Sensor Circuit Low Input

- P0193: Fuel Rail Pressure Sensor Circuit High Input

Hard to Start, or Won’t Start at All

A diesel engine needs a certain minimum fuel rail pressure to fire up. When you turn the key, the ECM tells the fuel system to build that initial pressure. A good sensor will confirm the pressure’s hit the right level, and then the ECM lets the injectors spray fuel to start the engine.

If the sensor’s bad and falsely reads low pressure (even if the actual pressure is fine), the ECM will stop the injectors from working as a safety step—this means the engine cranks but won’t start. On the flip side, if the sensor’s stuck reading high pressure, the ECM won’t tell the fuel pump to work right either, and that’ll also keep the engine from starting. This is one of the most confusing signs of a bad sensor, because the engine sounds like it’s going to start, but just never fires up.

Poor Engine Performance and Loss of Power

Your excavator’s power for digging, lifting and moving all comes down to whether the engine can pump out enough power when it’s needed. The ECM uses the fuel rail pressure sensor to figure out if it needs to feed more fuel to the engine when it’s under heavy load.

If the fuel rail pressure sensor goes bad and sends the ECM a false low-pressure signal, the ECM will think the fuel pressure is too low and cut back on fuel injection. The end result? The engine doesn’t get enough fuel, so it loses a ton of power and feels slow to respond. You’ll usually notice things like:

- Can’t lift heavy loads that used to be a breeze

- Engine strains and even stalls when digging hard ground

- Slow machine movements and laggy hydraulics

This is what’s called a lean fuel mixture—basically, not enough fuel for the engine’s needs. A lean mix doesn’t just kill your work efficiency; it also makes the engine run hotter under heavy load, and over time, that’ll wear out the internal parts a lot faster. If you don’t fix it right away, it could shorten the life of your engine and other key parts.

Poor Fuel Economy and Black Smoke

On the flip side, a faulty sensor might get stuck reading pressure lower than it actually is. When that happens, the ECM will make the high-pressure pump work overtime to “boost” pressure up to the target level. This makes the fuel rail too pressurized, and the engine ends up getting way more fuel than it needs. This rich fuel mix causes two big, costly problems right away:

- Horrible fuel economy: Your machine will burn way more diesel than normal, and that hits your operating costs hard.

- Lots of black smoke: The extra fuel can’t burn all the way in the engine. This unburnt fuel comes out as thick black smoke—total telltale sign of over-fueling in a diesel. It’s not just an eyesore; it can also clog up emissions parts like the DPF a lot faster than normal.

Engine Misfires and Rough Idling

If the sensor’s acting up and sending spotty, inconsistent signals, the ECM will end up adjusting fuel pressure all over the place—all wrong. The fuel being injected changes nonstop, making the engine run unsteadily. You’ll feel the engine idle roughly and vibrate, or even misfire noticeably.

Troubleshooting and Diagnosing a Failing Fuel Pressure Sensor

If you’re noticing these issues, a step-by-step check can help you confirm if the fuel rail pressure sensor’s the problem.

Check the Fault Codes

First, plug a diagnostic scanner into the machine’s diagnostic port. The stored codes will point you right to issues with the fuel rail pressure circuit.

Check Live Data

Use the scanner to pull up the ECM’s live data, and focus on Desired Fuel Rail Pressure and Actual Fuel Rail Pressure:

- Key on, engine off: both numbers should be close to zero.

- When cranking the engine: the actual pressure should jump up to match the desired pressure.

- When the engine’s running: the actual pressure should follow the desired pressure closely as the engine revs up or takes on load. If the reading is stuck, all over the place, or way off, the sensor’s probably bad.

Do a Visual Check

Look over the sensor’s wiring and connector for damage, rust, or loose connections. Also, check for fuel leaks around the sensor itself.

Rule Out Other Problems

Low fuel pressure isn’t always the sensor. Fuel filters or a Fuel pump can cause it too. If the pressure reading seems accurate but is just consistently low, the problem’s likely somewhere else in the fuel system.

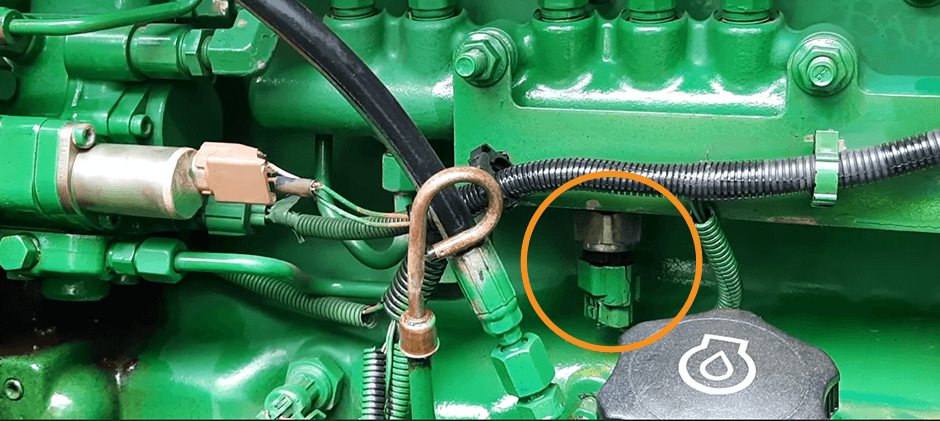

How to Locate the Fuel Rail Pressure Sensor?

Finding the sensor is usually easy. On all common rail diesel engines, the fuel rail pressure sensor screws right into the high-pressure fuel rail. That rail’s the thick metal pipe that sends fuel to all the injectors. Just look for a small sensor with an electrical plug on it—it’s almost always at one end of the rail.

Can You Operate With a Faulty Fuel Rail Pressure Sensor?

Even if the engine still runs and you could limp the machine back to the shop, never keep using it if you know the sensor’s faulty.

- Engine damage risk: Running lean nonstop makes the engine overheat, which can wreck pistons and valves. Running rich washes the lubricating oil off cylinder walls, leading to early wear and tear.

- Safety hazards: If the engine stalls out of nowhere—especially when lifting a load or moving on a slope—it’s a huge safety risk.

- Higher costs: Bad fuel economy eats straight into your profits, and keeping the machine running could cause a far worse, more expensive breakdown later on.

Replacing the sensor right away is the only smart move. It protects your equipment, and keeps your job site safe and efficient.

How Much Does a Fuel Rail Sensor Cost?

Replacing a fuel rail pressure sensor means the part’s cost can vary a lot. The final price depends on your machine’s brand and model, its specific engine, and most importantly, whether you go for an OEM part from a dealer or a good-quality aftermarket one.

OEM parts are sold straight by the equipment maker, and they usually cost the most. Aftermarket parts, though, are made by independent companies to meet or even beat OEM standards—they’re way more budget-friendly, and just as reliable. Here’s a breakdown of theprice ranges for the sensor only:

| Equipment Type | Aftermarket Price Range | OEM Price Range |

|---|---|---|

| Excavator | $70 – $150 | $250 – $450 |

| Wheel Loader | $90 – $220 | $400 – $650 |

| Dozer | $120 – $300 | $550 – $800+ |

| Agricultural Tractor | $85 – $250 | $350 – $700 |

Note: These prices are as of early 2026 and can vary by specific engine model and supplier.

As you can see, going with a quality aftermarket fuel rail pressure sensor saves you a ton of money. You’ll get your machine back up and running in no time, and it won’t cost you an arm and a leg.

Get a Fuel Rail Pressure Sensor

A faulty fuel rail sensor will hurt your engine’s performance. You may also have trouble starting your equipment, so don’t put off replacing it. It’s super easy to buy a fuel rail pressure sensor at FridayParts. Just type the brand and model into the search bar, and you’ll find fully compatible parts right away.