Whether it be the hydraulic pump that drives the excavator, the cooling fan that rotates upon the bulldozer, or the attachment that receives power upon the loader, all are of indispensable significance to the power transmission system. The two most prevailing manners of transmission are the belt drive and the chain drive. The choice between a belt and a chain shall exert influence upon the machine’s performance, maintenance routine, and the expense of long-term operation. This guide shall unravel the working principles of each system, conduct a comparison of their key performance indices, and assist you in discerning which system best suits the manifold applications of your off-road machine.

How Does the Belt and Chain Drive Work?

Before we go to compare them, we must first comprehend the essential mechanics of each system. Both are to transfer rotational motion from one shaft to another, yet their methods are vastly different in the world.

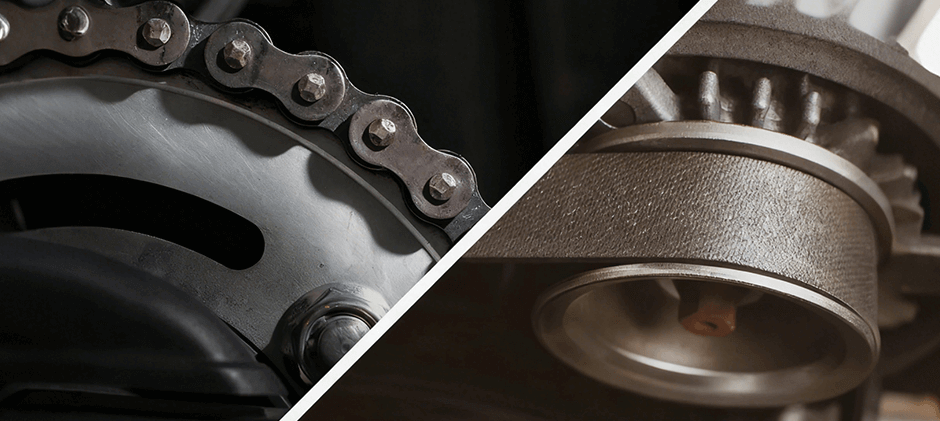

The Belt Drive: Power Transmitted by Friction and Fit

A belt drive system is composed of a flexible, continuous loop—called the belt—which runs upon two or more grooved wheels known as pulleys. Power is transmitted chiefly by the friction between the belt and the pulleys. When the drive pulley rotates, it grips the belt and drags it forward, thereby causing the driven pulley to turn.

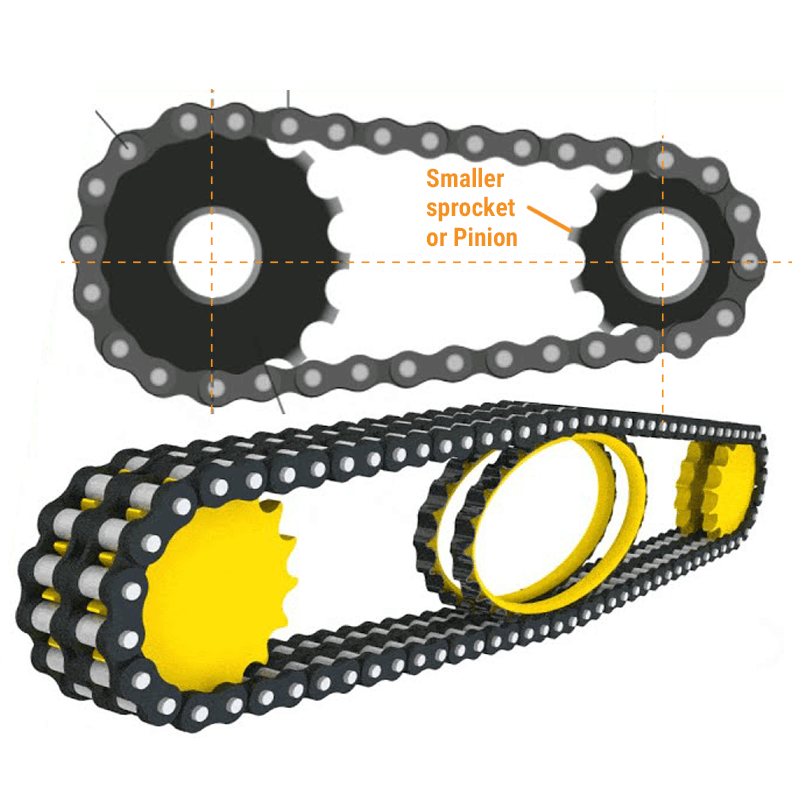

The Chain Drive: Power Transmitted by Positive Engagement

A chain drive system employs a chain made of interconnected metal links, engaging with toothed wheels called sprockets. Power is conveyed by the direct, positive engagement of the chain’s rollers with the teeth of sprockets. As the drive sprocket rotates, its teeth push against chain links, pulling the chain and forcing the driven sprocket to rotate in exact synchronization. No slip occurs in a properly tensioned chain drive. The most frequent type of machinery is the roller chain, appreciated for its strength and endurance under heavy load.

Belts vs Chains: Which One is Better?

The optimal choice is wholly contingent upon the specific application’s requisites regarding load, velocity, maintenance, and operating environment. Let us dissect the comparison across the factors of utmost significance to a proprietor of heavy apparatus.

-

Maintenance and Cleanliness

Belt drive manifests as the unambiguous victor in this regard. Belts necessitate no lubrication, thereby running in cleanliness. This constitutes a notable advantage in dusty locales, where lubricant may attract particulate matter and grit, forming an abrasive amalgam that accelerates wear upon chain components. Chains, conversely, mandate routine lubrication to obviate corrosion and mitigate friction among their pins, rollers, and bushings. Such a procedure is both untidy and time-consuming.

-

Noise and Vibration

Belts operate with considerably diminished noise and vibration. The elastic and flexible substance of a belt absorbs shocks and runs with smoothness over pulleys. Chains, being a concatenation of metal-to-metal contacts, are intrinsically noisier and generate more vibration, particularly at elevated speeds. For operations within an operator’s cabin or adjacent to sensitive electronic apparatus, the more silent operation of a belt drive is often favored.

-

Load Capacity and Torque

Herein lies the superiority of the chain drive. Owing to their fully metallic construction and positive engagement, chains accommodate substantially higher torque and endure greater shock loads than belts. This renders them the preferred selection for final drives, heavy-duty conveyors, and other applications wherein tremendous force must be transmitted devoid of slippage risk. While advanced synchronous belts are progressively narrowing the performance gap, conventional roller chains remain preeminent in sheer mechanical might.

-

Operating Speed

Belts are generally better attuned to high-velocity applications. They are of lighter constitution and may function at markedly higher RPMs than a heavy roller chain before vibration and centrifugal effects become troublesome. Hence, belts are commonly employed for engine adjuncts such as alternators, water pumps, and cooling fans, driven directly by the engine’s high-speed crankshaft pulley.

-

Operating Conditions and Alignment

Chains exhibit greater tolerance to rigorous environments. They are less susceptible to temperature fluctuations, and although they are rust-prone, they do not degrade as readily from exposure to oil or chemicals as certain belt materials. Belts, in contrast, may become brittle under extreme cold or elongate under high heat. Moreover, chain drives are marginally more forgiving of minor shaft misalignment, whereas belt drives necessitate precise alignment to forestall premature wear and to secure correct tracking.

Difference Between Belt Drive and Chain Drive

To make the comparison easier, here is a summary table highlighting the key differences:

| Feature | Belt Drive | Chain Drive |

|---|---|---|

| Principle | Friction or Toothed Fit | Positive Engagement |

| Maintenance | Low (no lubrication needed) | High (requires regular lubrication) |

| Noise Level | Low | High |

| Load Capacity | Moderate to High | Very High |

| Speed | Excellent for High Speeds | Best for Low to Moderate Speeds |

| Slippage | Possible (V-belts), None (Timing belts) | None (if properly tensioned) |

| Efficiency | 94-98% (can be lower with slip) | 95-99% |

| Cost | Generally, lower initial cost | Generally higher initial cost |

| Lifespan | Good, but can be shortened by heat/oil | Excellent, very durable |

| Alignment | Requires precise alignment | More tolerant of minor misalignment |

| Environment | Sensitive to oil, chemicals, extreme temps | More robust in harsh environments |

Sourcing Parts for Your Belt Drive System

The serpentine belt, which drives the alternator and fan, the V-belt on the hydraulic pump, and the timing belt within the engine are all of quintessential importance. When replacement becomes requisite, one is necessitated to procure a solution both dependable and perpetually available. Pulley wear, if existing, is capable of destroying a newly installed belt within mere hours. The replacement of multitudinous components may culminate in a not insignificant expenditure. While OEM (Original Equipment Manufacturer) parts perpetually remain an option, aftermarket suppliers of elevated quality are able to present alternatives within a reasonable budget, in terms of both price and availability.

Whether the requirement is merely for routine maintenance belt replacement, or for the substitution of a newly belt pulley, the acquisition of a specific fan pulley to reestablish engine cooling efficiency, or the procurement of a complete timing kit for major engine overhaul, reputable aftermarket providers such as FridayParts can furnish high-quality components meeting or surpassing OEM specifications, at more economical pricing, enabling your machinery to resume operation with alacrity, without compromise to performance or reliability.

Conclusion

In the debate between belt transmission and chain transmission, there is no absolute victor. Chains are suitable for applications of high torque and heavy load, wherein force is of paramount significance. Belts, conversely, are the optimal choice for high-speed, low-noise systems, as these systems prioritize minimal maintenance and smooth operation. By apprehending the respective advantages and shortcomings of each transmission modality, one can more thoroughly comprehend why engineers elect a particular system for each task upon your machinery, and maintain it correspondingly.