If you operate tractors, loaders, or any off‑road machinery that powers attachments, you’ve probably worked with a PTO system. Act as a crucial link; it connects your engine and its implementations. But here’s the common question we get every week: What’s the difference between a 540 and a 1000 RPM PTO shaft, and which one fits my machine? Knowing PTO speeds is more than just technical know‑how — it’s key to your machine’s performance, fuel efficiency, and safety. Let’s make it simple.

What Is a PTO and How Does It Work?

The PTO system transfers engine power to an attachment through a rotating shaft.

This single component lets one tractor handle countless jobs — from mowing and digging to pumping and baling.

When your PTO is engaged, the splined shaft at the rear of your tractor spins, powering the implement connected by a PTO drive shaft.

Different tractors use different PTO engagement types:

Transmission PTO Shaft

- Directly connected to the tractor’s transmission.

- PTO turns only when the clutch is engaged.

- Common in older or smaller tractors.

- Best for lighter tasks where constant power isn’t needed.

Independent PTO Shaft

- Has its own clutch system — works even when the tractor stops.

- You can start or stop the implementation anytime.

- Found on most modern tractors.

- Perfect for jobs that need steady power, like balers and spreaders.

If you want to select a PTO shaft, read the guide: How to Choose the Right PTO Shaft for Your Tractor?

540 vs. 1000 RPM PTO Shaft: What’s the Real Difference?

Both PTO speeds transfer engine power to your attachments — but they’re built for very different workloads.

Think of your PTO system like the gears on a bicycle:

- 540 RPM is your low gear — it spins slower but delivers stronger torque. Perfect for everyday tools that need extra pulling power, like mowers and augers.

- 1000 RPM is your high gear — faster rotation with less torque per revolution, making it ideal for bigger, high‑horsepower implements.

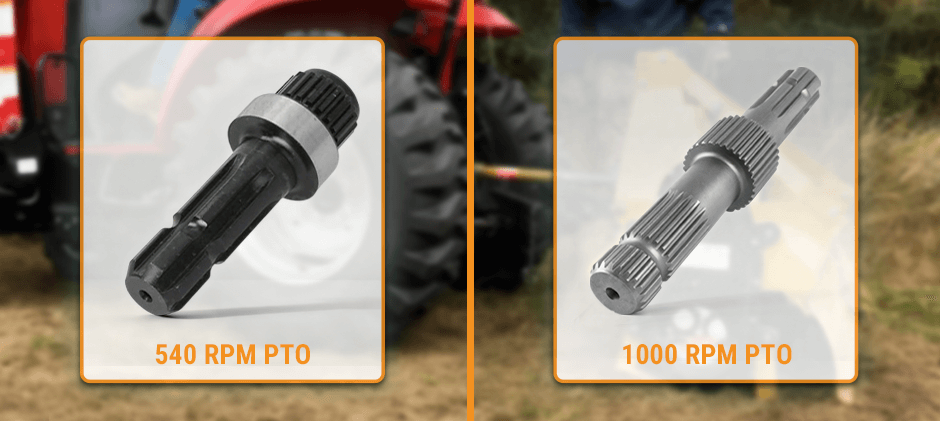

You can also see the difference just by looking at the shafts:

- 540 RPM shafts have 6 splines.

- 1000 RPM shafts have 21 splines.

This physical design acts as a built‑in safety system — the two sizes are not interchangeable, so you can’t accidentally connect an implement to the wrong PTO speed. That simple engineering safeguard helps prevent damage and keeps you safe in the field.

Why Most Off‑Road Machines Use 540 RPM PTO Shaft

For the majority of compact and mid‑sized tractors, 540 RPM is the go‑to.

- Versatility: Works with thousands of common attachments — rotary cutters, post‑hole diggers, spreaders, etc.

- Compatibility: Most implements under 75 HP are built for 540 RPM.

- History & Availability: It’s the long‑standing industry standard — especially for small farms and worksite machines.

You’ll only need 1000 RPM when you’re running high‑capacity, high‑horsepower equipment like large balers, forage harvesters, or heavy slurry pumps.

Why Is Choosing the Right PTO Shaft Important?

Never connect a 540 implement to a 1000 RPM PTO.

Doing so could double the speed your attachment expects, causing:

- Severe mechanical failure: Blades and gears can tear apart.

- Serious safety risks: High‑speed metal fragments can cause injury.

Running a 1000 RPM implement on a 540 PTO, on the other hand, isn’t dangerous — just inefficient. The equipment will underperform, wasting time and fuel.

Rule of thumb: Always match your PTO speed to your implement’s rating.

How to Engage / Disengage Your PTO Shaft

Engaging the PTO

- Check Connection: Make sure the PTO shaft is properly seated and shields are in place.

- Start at Low Idle: Reduce RPM before engaging to minimize shock.

- Press Clutch (if manual): Fully depress clutch.

- Engage Smoothly: Turn on PTO gradually; listen for unusual sounds.

Disengaging the PTO

- Return to Idle: Reduce engine RPM.

- Let It Wind Down: Wait for the implement to stop spinning.

- Switch Off PTO: Disengage lever or button.

- Engine Off Before Adjustments: Never handle PTO parts with the engine running.

PTO Adapters

Adapters can convert between 6‑ and 21‑spline shafts, but always check power ratings. Mismatched adapters can create stress on driveline components and lead to early failure. If you’re unsure — contact FridayParts Support. We’ll help you find the safe, correct part for your setup.

Final Thoughts

In the 540 vs 1000 RPM discussion, there’s no universal “better” — only the right PTO for your machine and job.

- Use 540 RPM for general‑purpose equipment.

- Choose 1000 RPM for large implements and tractors over 75 HP.

- Always follow safe engagement practices — and keep your PTO system in top condition with the right replacement parts.

Whichever PTO fits you, FridayParts has you covered. Visit our one-stop online shop to choose the reliable and cost-effective PTO shafts for your equipment right now!